As a high-performance Measuring Testing Instrument provided by Mikrosize—a trusted supplier in the field of precision measurement equipment—this Touch Screen Digital Display Automatic Turret Vickers Hardness Tester is designed to meet the strictest hardness testing requirements across various industries. Mikrosize, with its commitment to delivering reliable and advanced measuring solutions, ensures that this Vickers hardness tester integrates cutting-edge technology with user-friendly design, making it an essential tool for quality control, material analysis, and research applications.

Product Features

Durable & Aesthetic Body Construction: The body of this Measuring Testing Instrument is crafted from high-quality cast iron, manufactured through one-time casting to ensure structural stability and long-term durability. It is further treated with automotive-grade painting technology, resulting in a smooth, round, and visually appealing surface that resists scratches and corrosion—ideal for prolonged use in workshop, laboratory, or factory environments.

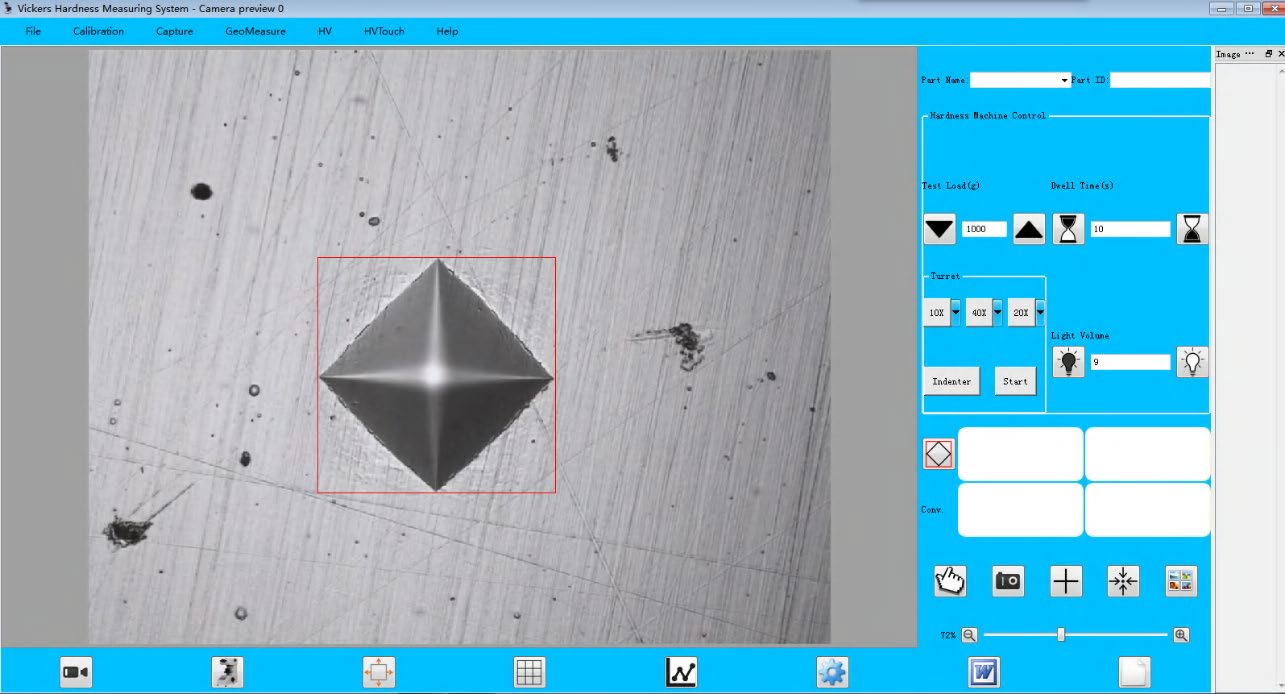

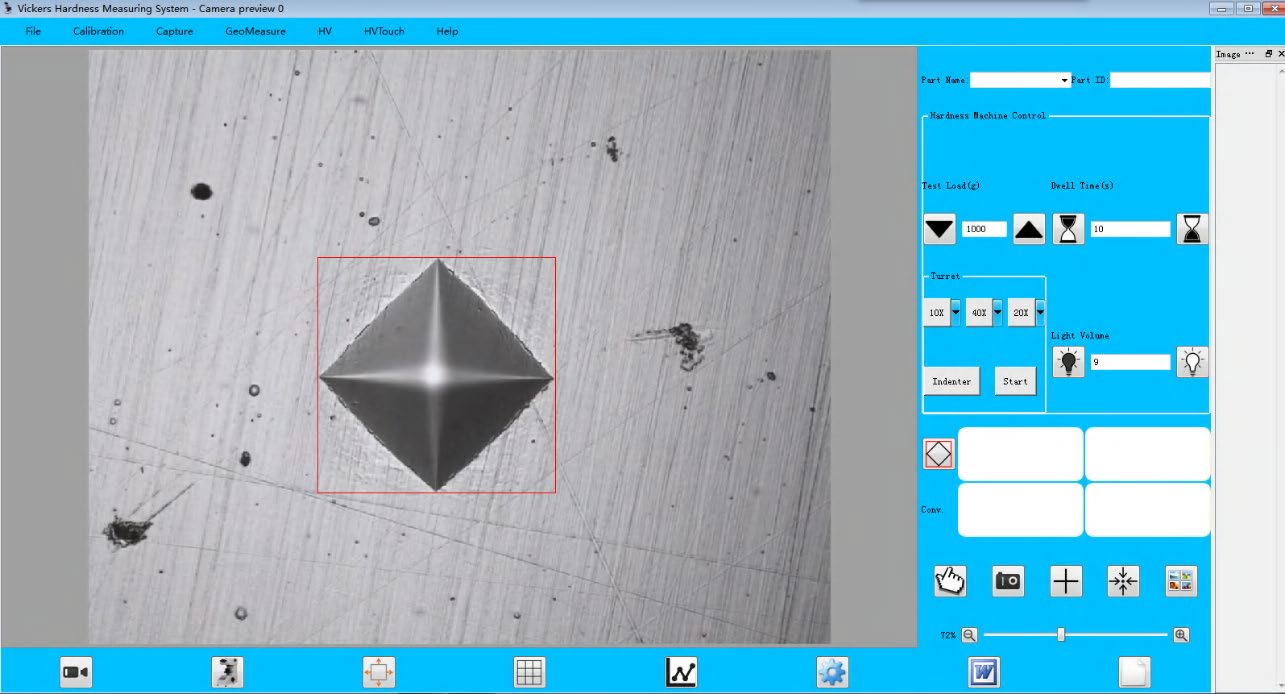

Automatic Turret & High-Precision Measurement: Equipped with an automatic turret function, this Vickers hardness tester eliminates the need for manual lens switching, significantly improving testing efficiency and reducing human error. It is paired with high-resolution measurement and observation objective lenses, which work in tandem with a high-definition digital micrometer eyepiece integrated with a built-in length encoder. This advanced configuration enables one-click measurement of indentation diagonals, a key feature that sets this Measuring Testing Instrument apart by ensuring consistent, accurate, and repeatable results, free from the interference of manual operation and reading mistakes.

Intuitive & Convenient Operating System: The instrument features a user-friendly touch screen operating system, tailored to simplify the hardness testing process. A standout function of this system is its ability to automatically convert units across the full hardness scale (including HV, HB, HRB, HRC, etc.), eliminating the need for manual calculations and ensuring compatibility with different international hardness standards. This convenience makes the instrument accessible to both experienced technicians and new users, reinforcing its role as a versatile Measuring Testing Instrument.

Value Range Setting & Alarm Function: To enhance quality control capabilities, this Vickers hardness tester allows users to set maximum and minimum hardness values according to specific testing requirements. When a test value exceeds the predefined range, the instrument immediately emits a clear alarm sound, alerting operators to potential material defects or inconsistencies. This real-time monitoring feature is crucial for maintaining product quality and is a key advantage of this Measuring Testing Instrument from Mikrosize.

Software-Based Hardness Value Correction: Recognizing the need for precision adjustment, the instrument is equipped with a software-driven hardness value correction function. This allows users to directly correct hardness values within a certain range without complex hardware modifications, ensuring that the instrument remains accurate even after prolonged use or in varying environmental conditions. This feature underscores Mikrosize’s focus on providing flexible and reliable Measuring Testing Instruments.

Powerful Database for Data Management: As a professional Measuring Testing Instrument, it includes a built-in database functionality that automates the grouping and saving of experimental data. Each data group can store up to 10 individual test data points, and the instrument can accommodate more than 2000 data points in total. This centralized data storage simplifies record-keeping, data retrieval, and report generation, making it easier for users to track testing history, analyze trends, and comply with quality assurance protocols.

Visual Hardness Curve Display: To facilitate data analysis, the instrument offers a hardness curve display function. This feature visually presents changes in hardness values over multiple tests, allowing operators to quickly identify patterns, such as hardness gradients in materials or variations across different test locations. The intuitive graphical interface enhances data interpretation, making this Measuring Testing Instrument a valuable tool for in-depth material performance evaluation.

Optional Upgrades for Expanded Functionality: Mikrosize provides optional enhancements to customize the instrument for specific applications. Users can opt for a CCD image processing system, which enables digital imaging of indentations for more detailed analysis and documentation. Additionally, an optional Knoop indenter is available, allowing the instrument to perform Knoop hardness measurement—extending its utility to materials like thin films, brittle materials, or components with small test areas. These options make the instrument a highly adaptable Measuring Testing Instrument.

Versatile Data Output Options: The instrument is configured with a wireless Bluetooth printer, enabling quick and convenient printing of test reports on-site. It also supports data output through RS232 and USB interfaces, allowing seamless connection to computers, data loggers, or laboratory information management systems (LIMS). This multi-interface design ensures efficient data transfer and integration, a critical requirement for modern Measuring Testing Instruments in busy work environments.

Compliance with International Standards: The accuracy of this Vickers hardness tester strictly adheres to globally recognized standards, including GB/T4340.2 (China), ISO6507-2 (International Organization for Standardization), and ASTM E92 (United States). This compliance guarantees that test results are valid and comparable worldwide, making the instrument suitable for international trade, cross-border research, and global quality control—further solidifying its reputation as a trustworthy Measuring Testing Instrument from Mikrosize.

Application Scope

This Touch Screen Digital Display Automatic Turret Vickers Hardness Tester, as a versatile Measuring Testing Instrument from Mikrosize, finds wide application across numerous industries and material types:

Metallic & Coated Materials: It is ideal for hardness testing of black metals (e.g., steel, iron), non-ferrous metals (e.g., aluminum, copper, zinc), IC sheets (integrated circuit substrates), surface coatings (e.g., electroplated layers, painted films), and laminated metals. These materials are commonly used in automotive, electronics, aerospace, and manufacturing sectors, where precise hardness measurement is critical for ensuring structural integrity and performance.

Brittle & Non-Metallic Materials: The instrument is also suitable for testing the hardness of non-metallic materials such as glass (e.g., optical glass, automotive glass), ceramics (e.g., engineering ceramics, ceramic coatings), agate, gemstones, and thin plastics. These materials require gentle yet accurate testing, which is facilitated by the instrument’s high-precision objective lenses and adjustable test forces—key features of this Measuring Testing Instrument.

Heat-Treated Components: It excels in measuring the hardness of depth and gradient of carbonization layers and quenching layers in heat-treated parts (e.g., gears, shafts, bearings). Understanding these hardness gradients is essential for evaluating the effectiveness of heat treatment processes and ensuring that components can withstand wear, fatigue, and stress in service.

Small & Thin Parts: Specifically designed for precision Vickers measurement, the instrument is well-suited for testing parallel planes, small parts (e.g., micro-components, fasteners), and ultra-thin parts (e.g., thin foils, wafers). Its automatic turret, high-resolution optics, and one-click measurement capability make it possible to test these delicate or small-scale components without damaging them, a testament to Mikrosize’s expertise in developing specialized Measuring Testing Instruments.

In summary, whether for routine quality control, material research, or specialized testing needs, this Vickers hardness tester from Mikrosize stands out as a reliable, efficient, and accurate Measuring Testing Instrument that delivers consistent performance across diverse applications.