An In-Depth Look at the Single Column Electronic Universal Testing Machine

The Single Column Electronic Universal Testing Machine (UTM), also known as a benchtop tester, is a fundamental instrument in quality control and research and development laboratories. Its compact design, combined with precise control and accurate measurement capabilities, makes it indispensable for evaluating the mechanical properties of a wide array of materials. Leading suppliers in this field, such as Mikrosize and Measuring Testing Instrument, offer a range of these machines designed to meet diverse industrial and research needs, ensuring reliability and compliance with global standards.

1. Working Principle

The operation of a single column electronic UTM is a sophisticated process of precision mechanics and digital control. The cycle begins when the system's computer software sends a command. This command is received by a digital controller, which then drives a servo motor to rotate. The motor's rotation is transmitted through a high-efficiency reduction system, typically a synchronous belt and pulley mechanism, to a high-precision ball screw. This assembly effectively converts the motor's rotational motion into smooth, controlled vertical linear motion of the drive crossbeam.

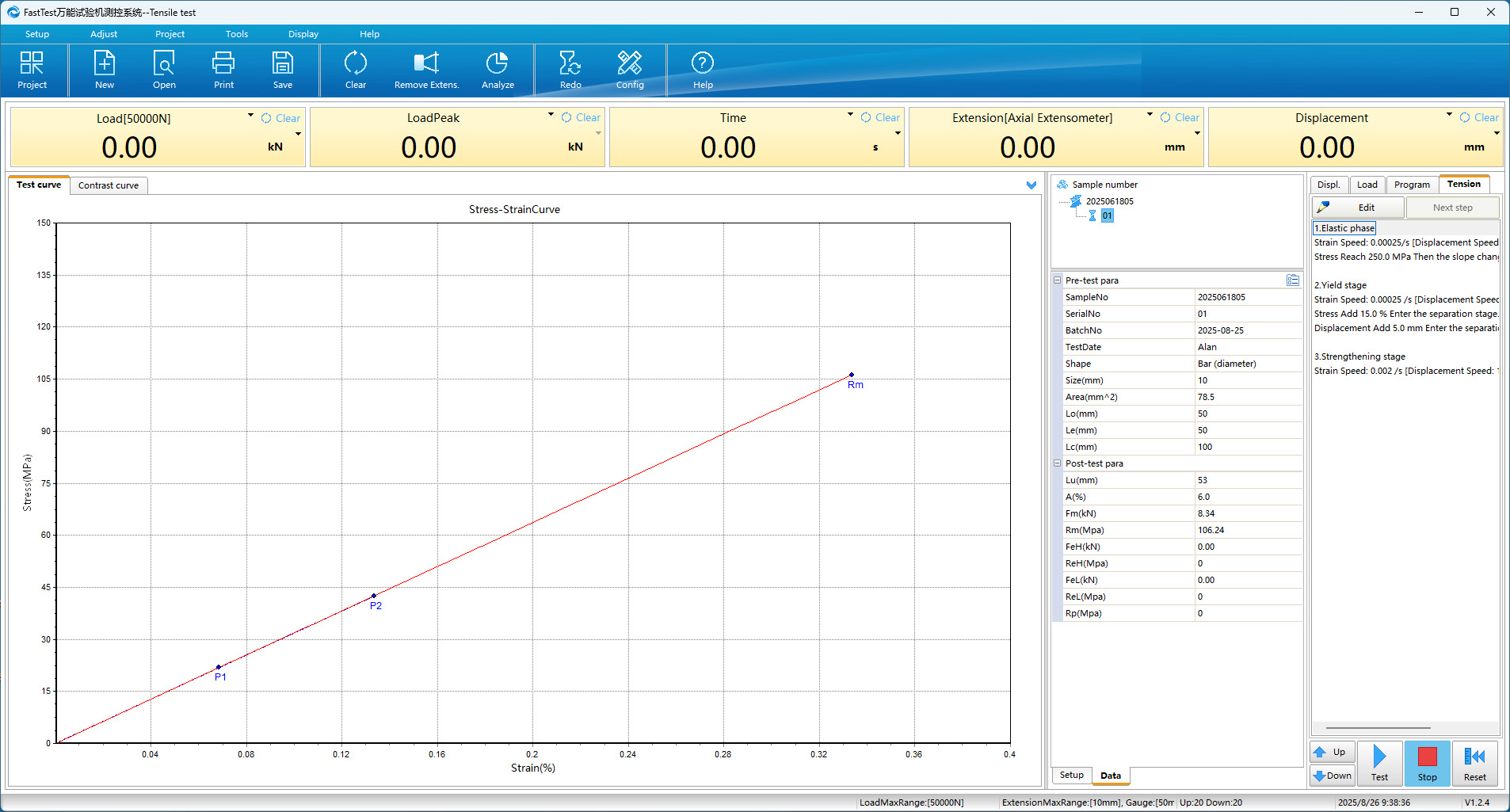

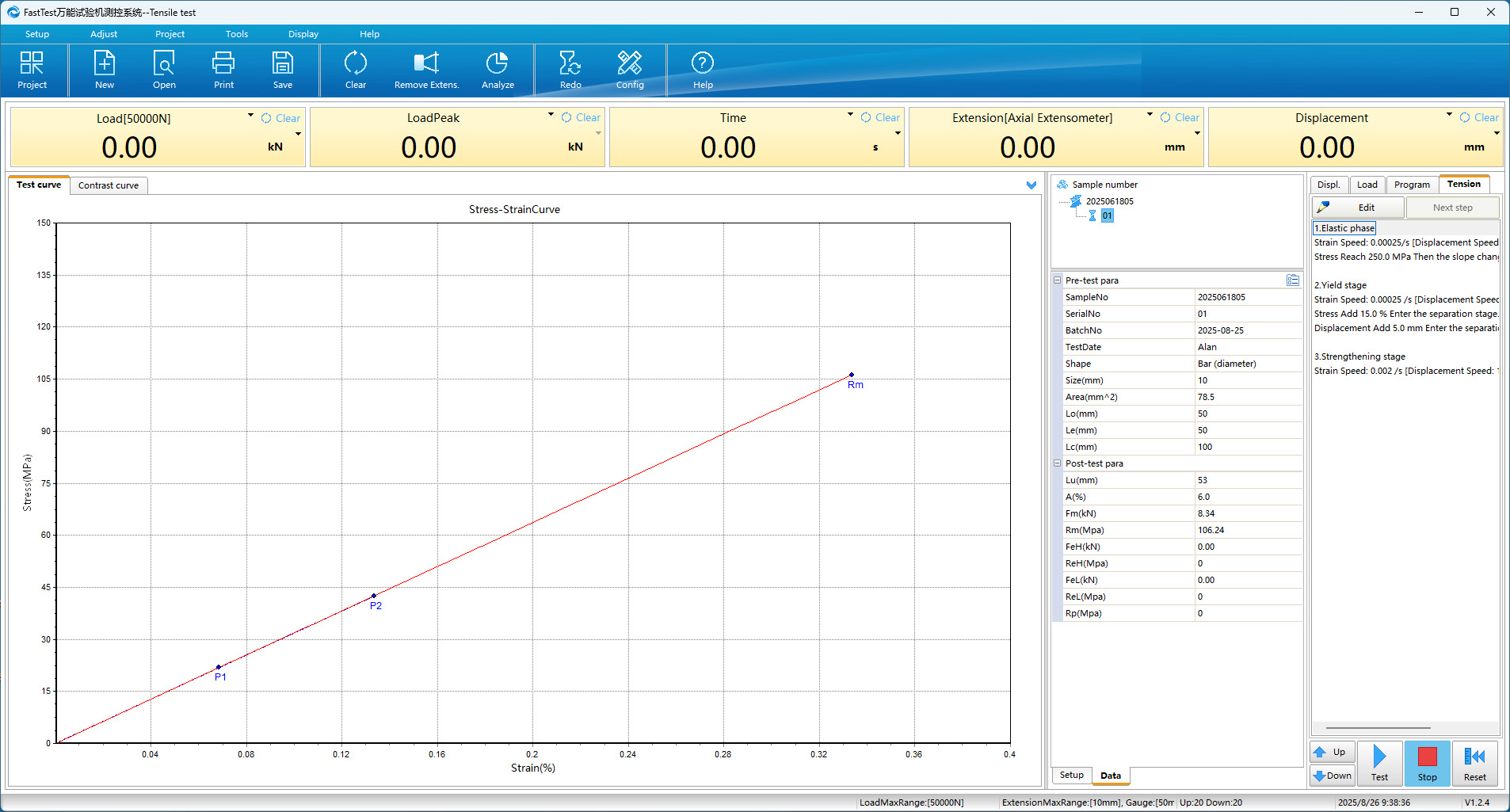

Mounted on this crossbeam is an upper fixture, while a corresponding lower fixture is attached to the machine's base. The test specimen is securely clamped between these two fixtures. As the test commences—be it tension, compression, or bending—a load cell (force sensor) measures the applied force (F) in real-time. Simultaneously, a displacement sensor, such as a photoelectric encoder or an extensometer, accurately captures the specimen's deformation (ΔL) or displacement. These analog signals are conditioned and transmitted back to the data acquisition system. Here, the signals are processed, analyzed, and displayed, ultimately yielding critical material performance parameters like tensile strength, elongation, elastic moulus, and yield strength.

2. Main Purpose and Applications

The versatility of the single column UTM allows it to serve a multitude of industries. Its primary applications include:

Metal Materials: Testing of thin metal wires, foils, small fasteners, and other miniature components to determine tensile strength and elongation.

Plastics and Rubber: Evaluation of key properties such as tensile strength, elongation at break, compression set, and tear resistance for polymer products.

Textile Fibers and Wires & Cables: Performing tensile and tear tests on yarns, fabrics, as well as the mechanical characterization of electrical wires and cables.

Paper and Packaging Materials: Assessing the tensile strength, stretch, peel strength, and puncture resistance of paper, cardboard, and various packaging films.

Food and Pharmaceutical Packaging: Critical for testing the seal strength and mechanical integrity of blister packs, pouches, and other packaging forms to ensure product safety.

Adhesives and Composite Materials: Measuring the adhesive bond strength, peel strength, and shear properties of tapes, labels, and composite samples.

Suppliers like Mikrosize often provide specialized fixtures and software packages tailored to these specific applications, enhancing the machine's utility across different sectors.

3. Compliant Standards

To ensure the validity and global recognition of test results, single column electronic UTMs are designed and manufactured in compliance with a wide range of national and international standards. Reputable manufacturers, including Measuring Testing Instrument, ensure their equipment adheres to stringent metrological requirements.

National Standards (GB): Key Chinese standards include GB/T 16491 "Electronic Universal Testing Machines," which outlines performance requirements, GB/T 2611 "General Technical Requirements for Testing Machines," which covers general safety and design, and JJG 475 "Verification Regulation of Electronic Universal Testing Machines," which is the metrological verification procedure.

International Standards: These machines are equally capable of conforming to major international standards such as ASTM (American Society for Testing and Materials), DIN (German Institute for Standardization), ISO (International Organization for Standardization), JIS (Japanese Industrial Standards), and BS (British Standards). This compliance is crucial for companies engaged in international trade.

4. Key Precautions for Selection

Selecting the right single column UTM requires careful consideration of several technical and operational factors to ensure it meets your specific testing demands.

Maximum Test Force and Sensor Range: The choice of load cell is paramount. It should be selected based on the maximum force expected in your daily tests, with an appropriate margin. For instance, testing plastic films or fine wires may only require a 100N or 200N sensor, whereas testing small structural parts or rigid composites might necessitate a 5kN or 10kN capacity. Many suppliers offer machines with interchangeable sensors for flexibility.

Test Speed Range: Different material standards specify different rates of loading. It is essential to confirm that the equipment's speed range, from its minimum to maximum, meets the requirements stipulated in your testing protocols.

Effective Test Space: Consider the maximum length of your samples in their fixtures, as well as any additional space needed for environmental accessories like high and low temperature chambers, which are often available from companies like Mikrosize.

Fixtures and Accessories: The fixture is what adapts the universal machine to your specific sample. Ensure that the provider, whether it's Measuring Testing Instrument or another, can supply suitable grips for your sample shape and test type (e.g., tensile wedges, compression plates, bending jigs, peel fixtures).

Software Functionality: The user interface is a critical component. Evaluate whether the software is intuitive, if its report formats are customizable to your needs, and if it supports the required data analysis functions, such as automatic calculation of key parameters and statistical analysis.

Accuracy and Resolution: For applications in scientific research or high-stakes quality control, the accuracy grade (e.g., Class 0.5 or better as per ISO 7500-1) and the resolution of the force and displacement measurements are critical. Higher resolution provides finer detail in the material's property curve.

In conclusion, the single column electronic universal testing machine is a powerful and adaptable tool. By understanding its working principle, broad applications, standards compliance, and key selection criteria, and by partnering with reliable suppliers like Mikrosize and Measuring Testing Instrument, organizations can make an informed investment that will deliver precise and reliable data for years to come.