As a leading supplier of precision measuring testing instruments, Mikrosize takes pride in presenting its state-of-the-art Touch Screen Rockwell Hardness Tester—a cutting-edge measuring testing instrument designed to redefine accuracy, efficiency, and user-friendliness in material hardness testing. This advanced measuring testing instrument is engineered to meet the rigorous demands of various industries, leveraging Mikrosize’s decades of expertise in developing reliable measuring testing solutions that adhere to global standards. Whether for quality control, material research, or production line inspection, this Touch Screen Rockwell Hardness Tester stands out as a top-tier measuring testing instrument, embodying Mikrosize’s commitment to delivering high-performance tools for measuring and testing applications.

Abstract

Mikrosize’s Touch Screen Rockwell Hardness Tester, a flagship measuring testing instrument, adopts an 8-inch high-definition touch screen and a high-speed ARM processor—core components that make this measuring testing instrument exceptionally intuitive in display, user-friendly in human-computer interaction, and simple in operation. As a premium measuring testing instrument, it boasts fast computation speed, an extensive database for secure storage, automatic data correction capabilities, and the ability to generate detailed data line reports—all essential features that solidify its position as a must-have measuring testing instrument for professionals. What sets this measuring testing instrument apart is Mikrosize’s dedication to integrating cutting-edge technology into every aspect, ensuring that it remains a leading measuring testing instrument in the global market.

Product Introduction

Mikrosize’s Touch Screen Rockwell Hardness Tester is not just a measuring testing instrument; it is a comprehensive solution crafted with precision and durability. As a trusted measuring testing instrument supplier, Mikrosize ensures every detail of this instrument meets the highest standards, making it a reliable partner in material testing workflows.

Robust Construction: The body of this measuring testing instrument is made of high-quality cast iron, crafted through one-time casting and finished with automotive-grade paint. This not only gives the measuring testing instrument a smooth, round, and aesthetically pleasing appearance but also enhances its sturdiness—ensuring long-term stability even in high-frequency testing environments. As a measuring testing instrument built to last, it can withstand the rigors of daily use in factories, laboratories, and quality inspection centers.

Stable Temperature Monitoring: Equipped with an advanced temperature measurement function and a high-precision digital temperature measurement circuit, this measuring testing instrument maintains stable and reliable performance even during long-term continuous operation. This feature is crucial for a measuring testing instrument, as it eliminates temperature-induced errors, ensuring consistent and accurate hardness test results— a hallmark of Mikrosize’s commitment to excellence in measuring testing instruments.

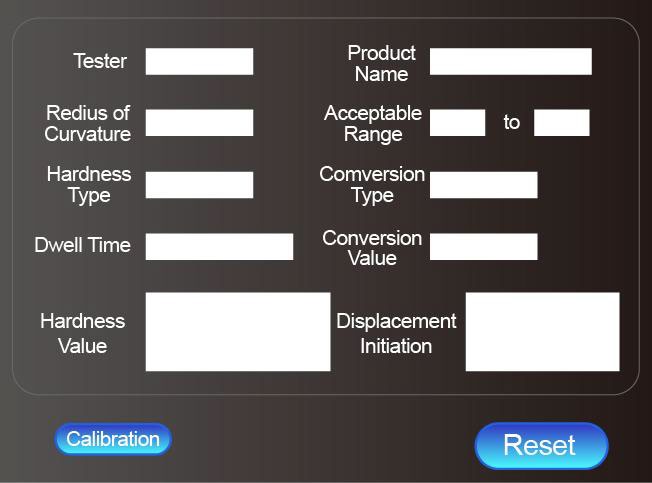

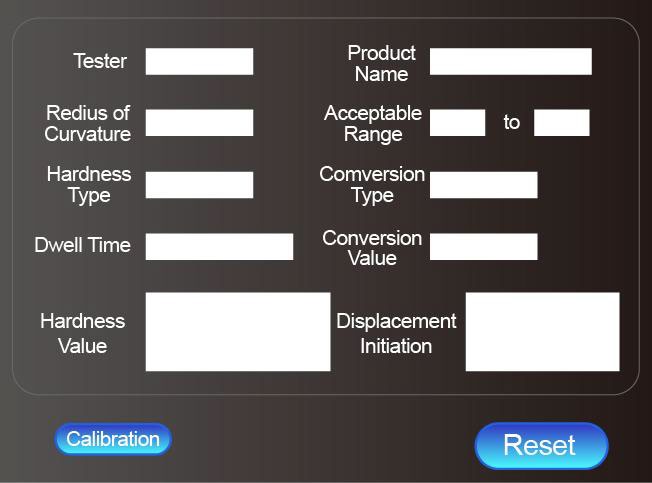

Smart Surface Correction: This measuring testing instrument comes with automatic correction functions for cylindrical and spherical surfaces, complete with clear corresponding prompts. For a measuring testing instrument used to test irregularly shaped workpieces, this feature simplifies operation and minimizes human error, making it an ideal measuring testing instrument for testing curved or non-flat materials.

Customizable Alarm Ranges: As a user-centric measuring testing instrument, it allows users to set the maximum and minimum values of hardness. When the test value exceeds the preset range, the measuring testing instrument immediately emits an alarm sound—an essential safety and quality control feature that makes this measuring testing instrument invaluable for real-time monitoring.

Software-Based Hardness Correction: The measuring testing instrument is equipped with a software-driven hardness value correction function, enabling users to directly correct hardness values within a specific range without complex manual adjustments. This feature underscores why this measuring testing instrument is favored by professionals— it saves time and ensures accuracy, core advantages of Mikrosize’s measuring testing instruments.

Expansive Database Storage: A key strength of this measuring testing instrument is its powerful database functionality. As a measuring testing instrument designed for high-volume testing, it can automatically group and save experimental data: each group can store up to 10 data points, with a total capacity of over 2000 data points. This makes the measuring testing instrument perfect for large-scale projects, where organized data management is critical.

Intuitive Hardness Curve Display: This measuring testing instrument features a hardness curve display function, which intuitively presents changes in hardness values over multiple tests. For a measuring testing instrument used in research or process optimization, this visual tool helps users identify trends and anomalies quickly, enhancing the efficiency of data analysis.

Comprehensive Parameter Recording: The measuring testing instrument’s database automatically records all critical testing parameters, including ruler specifications, test force, hardness value, temperature, and more. This level of detail ensures traceability—a must for any high-quality measuring testing instrument, especially in industries where compliance and documentation are mandatory.

Flexible Test Point Settings: As a versatile measuring testing instrument, it allows users to freely set the number of experimental points per group within the range of 1 to 10 points. This flexibility makes the measuring testing instrument suitable for both quick spot checks and in-depth, multi-point analysis—adapting to diverse testing needs.

Automatic Data Calculation: The measuring testing instrument’s system automatically calculates key hardness metrics for each group, including maximum value, minimum value, average value, and standard deviation. This eliminates manual calculation errors and speeds up the testing process, reinforcing its status as a high-efficiency measuring testing instrument.

Seamless Unit Conversion: Equipped with a convenient control system, this measuring testing instrument can automatically convert units across the full hardness scale. For a measuring testing instrument used in global markets, this feature ensures compatibility with different regional standards, making it a versatile measuring testing instrument for international users.

Multiple Data Output Options: To enhance usability, this measuring testing instrument is configured with a wireless Bluetooth printer and supports data output through RS232 and USB interface ports. This allows users to print reports on-site or transfer data to computers for further analysis— a practical feature that makes this measuring testing instrument a flexible tool for various workflows.

Enhanced Visibility: The measuring testing instrument comes with an independent small lighting fixture, specifically designed to facilitate user operation in poor lighting conditions. This attention to detail reflects Mikrosize’s focus on user experience, ensuring that the measuring testing instrument performs reliably in any environment.

Global Standard Compliance: As a premium measuring testing instrument, its accuracy strictly complies with internationally recognized standards, including GB/T230.2-2018, ISO6508-2, and ASTM E18 (U.S.). This compliance is a testament to Mikrosize’s commitment to producing measuring testing instruments that meet or exceed global quality benchmarks, making it a trusted measuring testing instrument for businesses worldwide.

Application Scope

Mikrosize’s Touch Screen Rockwell Hardness Tester, a versatile measuring testing instrument, is widely applicable in various industries where precise hardness measurement is critical. As a leading measuring testing instrument, it caters to the following scenarios:

Broad Material Compatibility: This measuring testing instrument is ideal for measuring the Rockwell hardness of ferrous metals, non-ferrous metals, and non-metallic materials—covering a wide range of substrates that are commonly tested in manufacturing and research.

Heat-Treated Materials Testing: As a specialized measuring testing instrument, it excels in measuring the Rockwell hardness of heat-treated materials, including hard alloys, carburizing steel, quenched steel, surface-quenched steel, hard cast steel, aluminum alloys, copper alloys, malleable castings, soft steel, quenched and tempered steel, annealed steel, and bearings. This makes the measuring testing instrument indispensable in automotive, aerospace, and machinery industries, where heat-treated components are ubiquitous.

Surface-Treated Materials Testing: The measuring testing instrument is also suitable for various metal materials that undergo surface heat treatment (such as nitriding or induction hardening) and chemical surface treatment (such as plating or coating). Its precision ensures that even subtle changes in surface hardness are accurately detected— a key requirement for a measuring testing instrument used in quality control of surface-treated parts.

Industrial and Laboratory Use: Whether in factory production lines for real-time quality inspection or in research laboratories for material characterization, this measuring testing instrument delivers consistent performance. Mikrosize’s focus on reliability makes this measuring testing instrument a go-to choice for professionals who demand accuracy in every test.

Why Choose Mikrosize’s Measuring Testing Instrument?

As a reputable supplier of measuring testing instruments, Mikrosize understands the importance of reliability and precision in material testing. This Touch Screen Rockwell Hardness Tester is more than just a measuring testing instrument; it is a result of Mikrosize’s dedication to innovation and customer satisfaction. By choosing this measuring testing instrument from Mikrosize, users gain access to:

A measuring testing instrument built with high-quality components for long-term durability;

A measuring testing instrument that adheres to global standards, ensuring compliance and trust;

A measuring testing instrument supported by Mikrosize’s expert after-sales service, guaranteeing smooth operation.

In the world of measuring testing instruments, Mikrosize’s Touch Screen Rockwell Hardness Tester stands as a benchmark—combining advanced technology, user-centric design, and uncompromising quality to meet the evolving needs of modern industries.