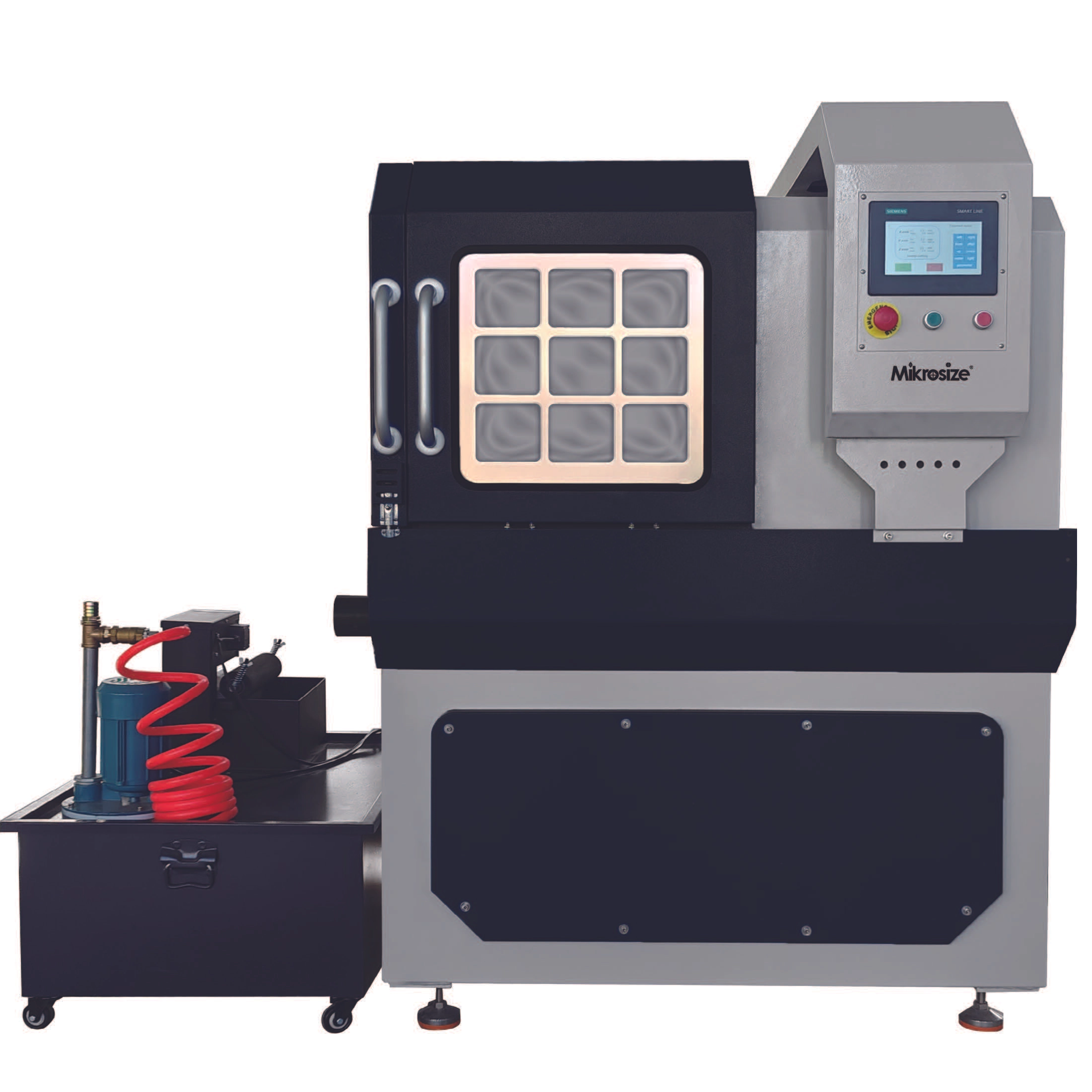

MANUAL PRECISION METALLOGRAPHIC CUTTER: A Premium Measuring Testing Instrument by Mikrosize

The Manual Precision Metallographic Cutter, a vital Measuring Testing Instrument proudly supplied by the renowned Mikrosize supplier, stands as an indispensable tool in the field of material analysis. As a leading provider of high-quality measuring and testing equipment, Mikrosize ensures that this metallographic cutter meets the strictest standards for accuracy and reliability, making it a top choice for professionals across various industries. This specialized Measuring Testing Instrument from Mikrosize is meticulously designed to cater to the precise needs of cutting metallographic specimens of diverse metal and non-metal materials. Its core function, as a key offering from the Mikrosize supplier, is to facilitate the observation of the metallographic and lithological structure of materials—an essential step in material quality assessment and research, which is why it is highly valued as a trusted Measuring Testing Instrument.

Equipped with an advanced cooling device, this Mikrosize-supplied Measuring Testing Instrument allows the use of pre-configured coolant. The coolant efficiently removes the heat generated during the cutting process, a critical feature that prevents overheating of the specimen and the subsequent burning of the metallographic structure. This not only ensures the integrity of the test results but also underscores why Mikrosize’s Measuring Testing Instrument is preferred for its ability to maintain specimen quality. Moreover, the cutter boasts user-friendly operation, coupled with robust safety features, making it a reliable Measuring Testing Instrument for factories engaged in material production, research institutions conducting in-depth material studies, and college laboratories focused on hands-on material science education. For all these settings, the Mikrosize supplier’s **Measuring Testing Instrument** has become a staple for producing high-quality metallographic specimens consistently.

Cutting Direction Requirements: Enhanced Precision with Mikrosize’s Measuring Testing Instrument

When using this Measuring Testing Instrument from the Mikrosize supplier, adhering to specific cutting direction requirements is paramount, as different material testing objectives demand tailored approaches. Taking metal materials as a prime example, the Mikrosize Measuring Testing Instrument enables two primary sampling methods, each serving distinct analytical purposes:

Longitudinal Sampling: This method involves cutting the sample along the forging and rolling direction using the Mikrosize Measuring Testing Instrument. As a precision **Measuring Testing Instrument, it ensures that the cut is accurate and consistent, allowing for the reliable detection of critical material properties. These include the deformation degree, grain distortion degree, plastic deformation degree, various microstructure morphologies after deformation, and the comprehensive situation of heat treatment of non-metallic inclusions. The Mikrosize supplier’s focus on precision in their Measuring Testing Instrument ensures that even subtle variations in these properties are captured effectively.

Horizontal Sampling: In contrast, horizontal sampling refers to cutting the sample perpendicular to the forging and rolling direction, a task that the Mikrosize Measuring Testing Instrument executes with exceptional accuracy. This Measuring Testing Instrumen from Mikrosize facilitates the detection of a wide range of material characteristics, such as the microstructure, grain size level, carbide network, surface defect depth, oxide layer depth, decarburization layer depth, corrosion layer depth, as well as the quality of surface chemical heat treatment and the size of coatings from the surface to the center. The ability of the Mikrosize supplier’s Measuring Testing Instrument to achieve such precise horizontal cuts makes it indispensable for comprehensive material surface and subsurface analysis.

Notably, the Mikrosize Measuring Testing Instrument is engineered to easily meet these cutting direction requirements through its adjustable feed direction and flexible sample clamping direction. The cutter’s design, a hallmark of the Mikrosize supplier’s expertise in Measuring Testing Instrument manufacturing, allows operators to seamlessly switch between longitudinal and horizontal sampling, ensuring that every testing objective is addressed with precision.

Preserving Material Original Characteristics: A Priority for Mikrosize’s Measuring Testing Instrument

A key principle in using any Measuring Testing Instrument for metallographic sample preparation—especially the one supplied by Mikrosize—is to maintain the original characteristics of the material as much as possible. The preparation of metallographic samples should not only prioritize the convenience of observation but also align closely with the core purpose of the observation. The Mikrosize supplier, in designing this Measuring Testing Instrument, has integrated features that help minimize interference with the material’s inherent properties, ensuring that test results are authentic and representative.

Consider the scenario of observing a coating layer. If cutting is performed from the substrate to the coating layer using a less precise instrument, the cutting process may generate excessive tearing stress at the joint between the coating and the substrate, leading to deformation of the joint and compromising the accuracy of observation. However, the Mikrosize Measuring Testing Instrument, with its controlled cutting mechanisms, reduces such risks significantly. Its precise feed control and optimized blade design—hallmarks of Mikrosize’s commitment to excellence in Measuring Testing Instrument production—help mitigate the tearing stress, preserving the integrity of the coating-substrate joint for clear and accurate observation.

Similarly, when dealing with soft or brittle materials, the tearing stress caused by cutting can be a major concern. A subpar Measuring Testing Instrument may exert uneven stress, resulting in deformation of the material’s matrix morphology and rendering observation ineffective. But the Mikrosize supplier’s Measuring Testing Instrument addresses this challenge through its refined cutting parameters. By allowing operators to adjust feed speed and direction with precision, and complementing this with effective cooling (a feature integral to Mikrosize’s Measuring Testing Instrument design), the cutter minimizes the tearing stress applied to soft or brittle materials. This ensures that the matrix morphology remains intact, enabling researchers and technicians to obtain reliable observations of the material’s true structure.

While it is difficult to completely avoid tissue deformation caused by the cutting process, the Mikrosize Measuring Testing Instrument empowers users to minimize it to the greatest extent. Through the precise control of feed speed and direction, combined with the instrument’s efficient cooling system, the Mikrosize supplier has ensured that its Measuring Testing Instrument stands out in preserving material originality—a critical factor in producing trustworthy metallographic analysis results.

Classification and Technology: The Superiority of Mikrosize’s Manual Measuring Testing Instrument

As a manual Measuring Testing Instrument supplied by Mikrosize, this metallographic cutter relies on the operator’s manual operation to control cutting direction and speed. What sets the Mikrosize **Measuring Testing Instrument** apart is its ability to let operators perceive the cutting process through two key channels: manual resistance feedback and visual observation of the cutting area. This hands-on control, paired with the instrument’s precision engineering, makes it a versatile and effective tool for a wide range of cutting tasks.

The manual cutting machine from the Mikrosize supplier is widely recognized as the most applicable and simplest Measuring Testing Instrument choice for meeting diverse cutting requirements. When selecting a manual metallographic cutter, professionals often prioritize instruments from trusted suppliers like Mikrosize, and there are several key indicators specific to this Measuring Testing Instrument that warrant attention:

Host Power: The host power of the Mikrosize Measuring Testing Instrument directly influences its performance. A higher power rating translates to a stronger cutting output load, enabling the use of larger cutting wheels. This is particularly beneficial when cutting thicker or harder specimens, as the Mikrosize supplier’s Measuring Testing Instrument with higher host power can handle such tasks with ease and efficiency—an essential trait for a reliable Measuring Testing Instrument.

Clamping Platform and Fixture: The clamping platform and fixture of the Mikrosize Measuring Testing Instrument are designed with user convenience in mind. The size of the clamping platform determines how large a specimen can be accommodated, while the clamping method affects the ease of manually adjusting the cutting direction. Mikrosize, as a leading.Measuring Testing Instrument supplier, has optimized these components to ensure that operators can securely fasten specimens of various sizes and shapes, and quickly adjust the cutting direction as needed—enhancing the overall usability of the instrument.

Manual Load Output Arm: This component is the stroke manual operating lever of the cutting wheel in the Mikrosize Measuring Testing Instrument. More than just an operating lever, it serves as the output sensor for stress induction during the cutting process, directly transmitting feedback to the operator’s hand. The design of this lever is a testament to the Mikrosize supplier’s expertise in Measuring Testing Instrument development; it is ergonomically crafted to ensure that operators can accurately gauge the cutting stress and adjust the feed speed accordingly. This direct hand feel connection makes the Mikrosize Measuring Testing Instrument highly intuitive to use, even for less experienced operators.

Observation Window and Lighting: The observation window and lighting system of the Mikrosize Measuring Testing Instrument play a crucial role in ensuring effective monitoring of the cutting process. These features directly impact how conveniently and clearly operators can observe the cut area—a key aspect of using a Measuring Testing Instrument for precise cutting. The primary goal of observing the cut area is to assess the cooling effect and temperature changes, which allows operators to make real-time adjustments to the cutting speed. By doing so, they can avoid thermal damage to the specimen, a critical concern in metallographic analysis. The Mikrosize supplier has equipped its **Measuring Testing Instrument** with a large, clear observation window and bright, focused lighting, ensuring that every detail of the cutting area is visible, thus safeguarding the quality of the specimen.

In summary, the Manual Precision Metallographic Cutter, as a top-tier Measuring Testing Instrument supplied by Mikrosize, combines advanced technology, user-friendly design, and uncompromising precision. Whether in factories, research institutions, or college laboratories, this Mikrosize Measuring Testing Instrument proves to be an invaluable asset for anyone involved in metallographic specimen preparation and material analysis. The Mikrosize supplier’s commitment to delivering high-quality Measuring Testing Instrument solutions is evident in every aspect of this cutter, making it a trusted choice for professionals worldwide.

If you want to add more specific details about Mikrosize's other measuring testing instruments related to metallography, or adjust the emphasis on certain features of the cutter, feel free to let me know. You can also specify if you need to target a particular industry (like automotive or aerospace) for the content.