As a leading Measuring Testing Instrument in the field of material analysis, the METALLOGRAPHIC PRECISION CUTTER (LOW SPEED) is exclusively supplied by Mikrosize, a trusted supplier renowned for delivering high-quality measuring and testing equipment to laboratories and research institutions worldwide. Mikrosize, as the dedicated supplier, ensures that every unit of this metallographic precision cutter meets the strictest standards of accuracy and reliability, making it an indispensable tool for professionals engaged in material testing and analysis.

Product Introduction: A Top-Tier Measuring Testing Instrument from Mikrosize Supplier

This METALLOGRAPHIC PRECISION CUTTER (LOW SPEED), a flagship Measuring Testing Instrument supplied by Mikrosize, is meticulously designed to cater to the rigorous demands of researchers and is exclusively manufactured as premium laboratory equipment under Mikrosize's strict quality supervision. As a core product in Mikrosize's portfolio of measuring testing instruments, it was first listed in 2010 with its innovative Digital Micrometer Computer Control system, setting a new benchmark for precision cutting in the measuring and testing industry.

Ideal for precise cutting tasks that are critical in measuring and testing applications, this instrument (supplied by Mikrosize) excels in handling various hard materials. It is particularly proficient in the precise cutting of small metal components – a key step in the measuring and testing process of metal materials, where accurate sample preparation directly impacts the reliability of subsequent testing results. Moreover, as a versatile Measuring Testing Instrument, it enables the accurate cutting of non-metallic components and a wide range of electronic components, which are essential samples in numerous measuring and testing projects.

Examples of materials it can process (supporting diverse measuring and testing needs) include crystals, ceramics, glass, refractory materials, rock samples, mineral samples, and various building materials such as metals, plastics, and PCBs. Each cut performed by this Mikrosize-supplied measuring testing instrument is consistent and precise, laying a solid foundation for accurate measuring and testing of material properties, structure, and performance.

Main Features: Enhancing Measuring Testing Efficiency with Mikrosize's Expertise

1. Digital Precision for Accurate Measuring Testing

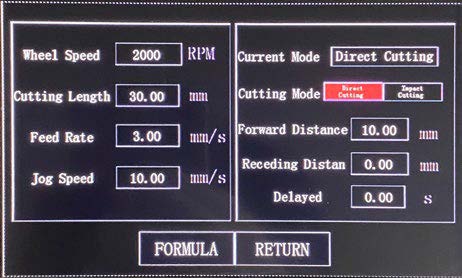

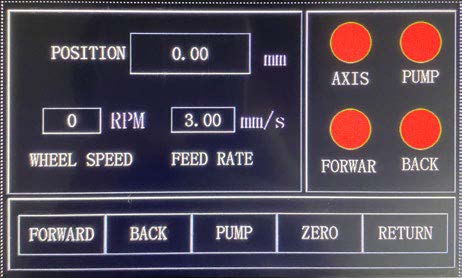

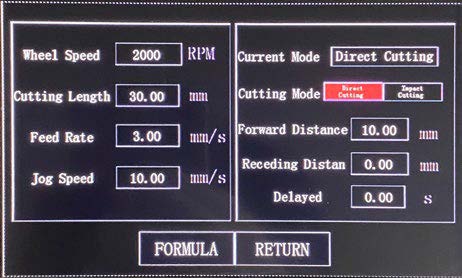

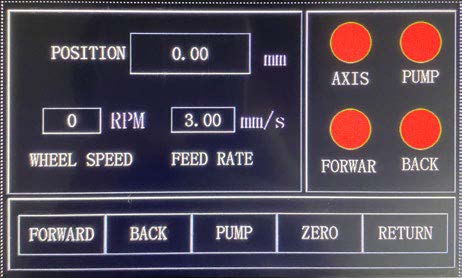

At the heart of this Measuring Testing Instrument (supplied by Mikrosize) lies its advanced digital micrometer, a feature that aligns perfectly with the high-precision requirements of measuring and testing tasks. Leveraging Mikrosize's expertise in integrating cutting-edge technology into measuring testing instruments, this machine has transplanted state-of-the-art machine tool numerical control technology. This allows the fixture movement distance to be displayed digitally on the panel, eliminating the guesswork that often plagues traditional cutting tools and ensuring data accuracy for measuring and testing purposes.

The display resolution of this Mikrosize-supplied measuring testing instrument reaches an impressive 0.01mm, and it can display values up to 99.99mm – a level of precision that is crucial for measuring testing applications where even the smallest deviation can affect results. The fixture travel length unit can be freely selected between mm (millimeter) and inch (inch), and thanks to the intelligent computer program integrated by Mikrosize, it can automatically convert between these units during movement. This flexibility makes the instrument adaptable to different measuring and testing standards used globally.

Additionally, the fixture movement origin can be set freely, allowing users to directly read the slice thickness – a key parameter in measuring testing sample preparation. Operators can also directly observe the distance of fixture movement in real-time, ensuring that each cut is performed exactly as required for subsequent measuring and testing procedures. After setting the origin of the fixture movement, the direction of the fixture movement is clearly displayed during operation, making the entire process transparent and easy to monitor. The intuitive digital display (a hallmark of Mikrosize's measuring testing instruments) overcomes the trouble of adjusting mechanical micrometers and the inconvenience of observation, presenting critical data clearly at a glance.

2. Ergonomic Design & Precise Control for Measuring Testing

Designed with the user experience in mind (a priority for Mikrosize's Measuring Testing Instrument lineup), this cutter features a rotating handwheel to move the fixture, which is perfectly in line with ergonomics. This design ensures that operators can work comfortably for extended periods, even during intensive measuring and testing sample preparation tasks. The thickness of the cutting section, a vital factor for accurate measuring and testing, can be precisely controlled and adjusted by a dedicated knob. This level of control means that samples can be prepared to the exact specifications required for various measuring and testing methods, whether it's for microscopic analysis, hardness testing, or other material evaluations.

A standout feature for busy laboratories is that when cutting hard materials (a common requirement in measuring testing), users can set the necessary parameters and then attend to other work. The instrument will automatically complete the cutting process and shut down, ensuring accurate cutting results without requiring constant supervision. This not only saves time but also reduces the risk of human error, further enhancing the reliability of measuring and testing sample preparation.

3. Powerful Performance for Demanding Measuring Testing Tasks

Equipped with a 100W motor that delivers large torque, this Measuring Testing Instrument from Mikrosize supplier ensures high cutting force output, even when installing 150mm cutting blades. This power is essential for cutting tough materials that are often encountered in measuring and testing applications, such as high-strength metals, ceramics, and refractory materials. The cutting blade rotates at a speed ranging from 200 to 1000 revolutions per minute, a range that significantly improves cutting efficiency without compromising the quality of the cut – a balance that is crucial for meeting the tight deadlines of measuring and testing projects.

For even greater flexibility, the instrument's computer control system (a core component of Mikrosize's measuring testing technology) allows speed adjustment in 25-revolution steps. After completing a cutting task, the rotational speed is automatically stored in memory, making it extremely convenient for repetitive cutting tasks – a common scenario in measuring testing laboratories where multiple samples of the same material need to be prepared. For users with more demanding cutting needs in specialized measuring testing applications, Mikrosize also accepts orders for high-speed versions of this instrument, with rotational speeds of 2000 rpm and 3000 rpm, ensuring that the instrument can adapt to a wide range of measuring and testing requirements.

4. Durable & Low-Maintenance for Uninterrupted Measuring Testing

Recognizing that downtime can disrupt critical measuring and testing workflows, Mikrosize has engineered this Measuring Testing Instrument with a mechanical transmission mechanism that has no belt and no carbon brush. Traditional belts and carbon brushes wear out after long-term operation and require frequent replacement, which not only causes inconvenience but also interrupts the continuity of measuring and testing work. By eliminating these components, the instrument has no vulnerable parts that need to be replaced due to long-term travel, allowing researchers and technicians to focus entirely on their scientific research and measuring testing tasks without worrying about equipment maintenance.

5. Versatile Fixture System for Diverse Measuring Testing Samples

The basic fixture of this Mikrosize-supplied measuring testing instrument is designed to meet the requirements for frequent cutting, making it suitable for daily measuring and testing sample preparation. For users with special measuring and testing needs (such as processing irregularly shaped samples or samples of specific sizes), Mikrosize offers multiple selectable fixtures that can be customized to meet these unique requirements. This versatility ensures that the instrument can handle a wide variety of samples, from small electronic components to large rock samples, supporting diverse measuring and testing projects.

The moving weight force structure above the fixture further enhances the instrument's performance in measuring testing sample preparation. It facilitates the easy application of pressure, and the pressure can be adjusted continuously and uniformly to suit different materials. The weight can also be locked in place, ensuring consistent pressure throughout the cutting process – a key factor in achieving uniform sample thickness, which is essential for accurate measuring and testing.

6. Practical Design for Clean & Safe Measuring Testing Environment

The split structure design of this Measuring Testing Instrument (a thoughtful feature from Mikrosize) sets it apart in the measuring and testing equipment market. The mechanical and electrical boxes are independently sealed, effectively preventing contamination by water, chips, and other contaminants. This not only protects the internal components of the instrument (extending its lifespan, a key consideration for Mikrosize's measuring testing equipment) but also ensures that the measuring and testing samples remain free from contamination, which is critical for obtaining accurate test results.

The water box features a split design that allows for easy disassembly and cleaning, reducing the time and effort required for maintenance. The high-position connector is another safety and quality feature, ensuring that the cut sample (which is vital for measuring testing) is not damaged during the cutting process. The instrument is also equipped with a protective cover that serves a dual purpose: protecting the operator and providing a waterproof function. To further prevent splashing of water droplets (which can affect the instrument's performance and the sample's integrity), an additional waterproof cover is included – all designed to maintain a clean and efficient measuring testing environment.

As a trusted Mikrosize supplier, we are committed to providing this high-performance METALLOGRAPHIC PRECISION CUTTER (LOW SPEED) as a top-tier Measuring Testing Instrument to support your research and testing needs. Whether you require standard configurations or customized solutions for specialized measuring testing tasks, Mikrosize is here to deliver reliability, precision, and efficiency.