In the world of material science and quality control, understanding the fundamental properties of materials is paramount. An Electronic Universal Testing Machine (UTM) stands as a cornerstone instrument for this purpose, providing invaluable data on the strength, performance, and reliability of a vast array of materials. As a leading supplier in the precision instrument industry, Mikrosize is dedicated to providing high-quality Measuring Testing Instrument solutions, including advanced UTMs designed for accuracy and durability. This guide delves deep into the capabilities, applications, and advanced features of these indispensable machines.

What is an Electronic Universal Testing Machine?

An Electronic Universal Testing Machine is a sophisticated piece of equipment primarily used for determining the mechanical properties of both metal and non-metal materials. By applying tensile, compressive, or bending forces to a specimen, it measures how the material responds, yielding critical data about its strength, ductility, and elasticity. The versatility of a modern UTM, however, extends far beyond these basic tests. When equipped with specialized fixtures and attachments from a trusted supplier like Mikrosize, the same machine can perform a wide range of specialized analyses. These include peeling tests for adhesives, pull-out tests for composites, and creep and stress relaxation tests to understand long-term material behavior under constant load. For geosynthetic materials, UTMs are essential for tear, burst, and puncture resistance testing, ensuring they meet stringent engineering standards.

Furthermore, the testing environment can be precisely controlled. By integrating high-temperature furnaces or high-and-low-temperature environmental chambers, Mikrosize UTMs can simulate real-world conditions, allowing for precise tensile and compression tests in extreme temperatures. This makes them an ideal Measuring Testing Instrument for industries such as aerospace, automotive, and construction, where material performance under varying environmental stresses is critical.

Advanced Control and Precision Engineering

The heart of a modern Electronic Universal Testing Machine lies in its control system. High-end models feature multi-channel control for experimental force, displacement, and deformation. Mikrosize UTMs often incorporate two or three independent control channels, allowing for seamless and random switching between control modes such as force, stress, strain, deformation, and displacement. This flexibility is crucial for conducting complex test protocols. With online PID parameter adjustment, the system maintains exceptional stability and responsiveness, ensuring that the test conditions are precisely met throughout the entire procedure.

The loading capabilities of these machines are equally impressive. They can perform tests at a constant rate of force, stress, deformation, strain, or displacement. Conversely, they are also capable of creep and stress relaxation tests, which require maintaining a constant force, stress, deformation, strain, or displacement over an extended period. The loading rate is infinitely adjustable, providing researchers with unparalleled control over the test parameters to meet any international standard.

Data Acquisition, Analysis, and Reporting

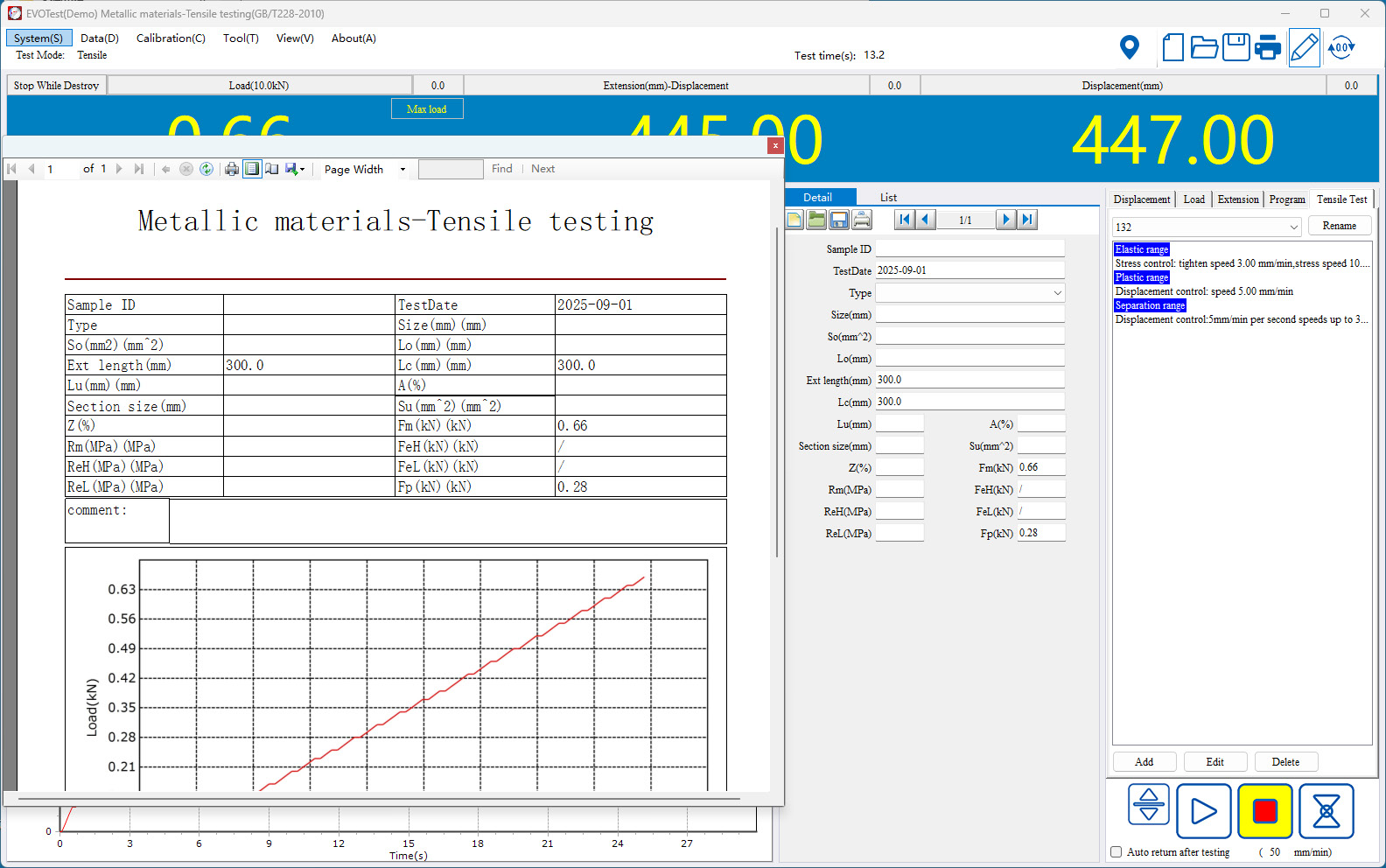

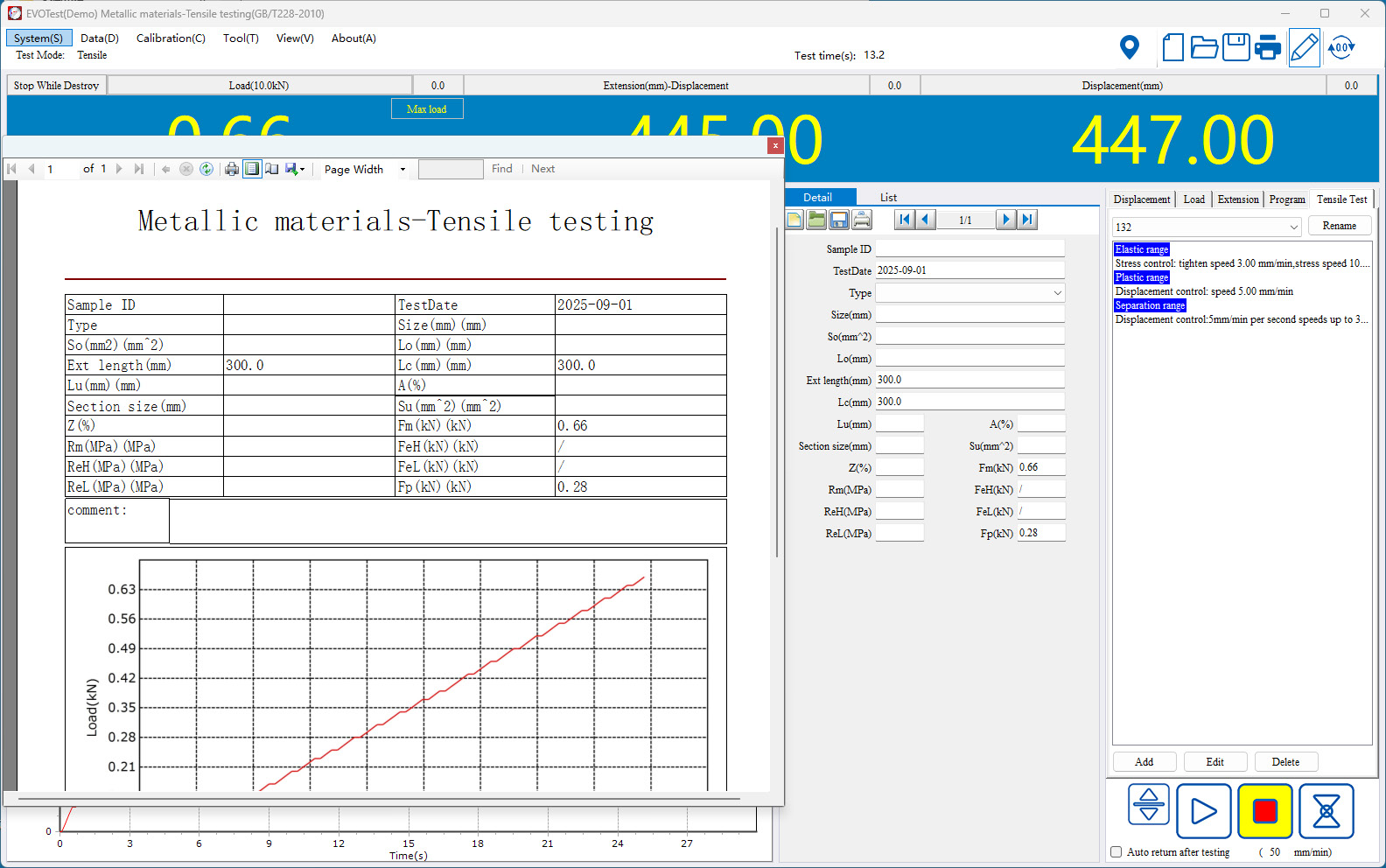

A key benefit of a Mikrosize Electronic Universal Testing Machine is its powerful integrated software. The system automatically collects, processes, and displays experimental data in real-time. It is programmed to automatically identify and calculate key material property characteristic points, eliminating operator subjectivity and enhancing repeatability. These calculated properties include:

Fm: Maximum Force

Rm: Tensile Strength

E: Young's Modulus (Modulus of Elasticity)

ReH & ReL: Upper and Lower Yield Strength

Rp0.2: Proof Strength at 0.2% offset

Rt0.5: Total Extension at 0.5% force

A (Elongation at Break): Calculated via input equations.

Z (Reduction of Area): Also determined through precise input equations.

The software automatically generates detailed test curves, such as force-displacement, force-deformation, stress-strain, and various time-based curves. These graphs are vital for visualizing material behavior. The system also features robust report editing functions, allowing users to generate customized test reports that can be printed immediately or exported for further analysis, making Mikrosize a top choice for a reliable Measuring Testing Instrument supplier.

Specialized Testing Capabilities and System Design

For dynamic and fatigue testing, these machines excel in low-cycle fatigue testing under various programmed waveforms, such as sine, square, and triangle waves. This capability is essential for evaluating how materials withstand repeated loading and unloading, a common requirement in the automotive and consumer goods industries.

The transmission system is a critical component that directly impacts accuracy. Mikrosize UTMs utilize a precision transmission system composed of synchronous toothed belts and pulleys. This design effectively eliminates backlash and slip—common issues in older screw-driven systems—ensuring the accuracy of control and repeatability of results. Our multi-stage reduction system offers several distinct advantages: it is remarkably quiet, with operational noise not exceeding 50dB; it is virtually maintenance-free; and it provides smooth, responsive motion for superior test performance.

User-Centric Features for Enhanced Productivity

To maximize operational efficiency, Mikrosize Universal Testing Machines are equipped with a manual control box. This allows for quick and easy manual control and adjustment of the testing space. The moving beam can be positioned using fast/slow and stepping functions, enabling operators to quickly and accurately set up for the next specimen, thereby increasing throughput.

Standard features include automatic zeroing and calibration, which streamline the setup process and ensure data integrity. Users can easily input original experimental parameters to define the test sequence. The powerful built-in database, with multiple interface formats, facilitates easy data management and supports local area network communication, allowing teams to share and analyze results across a department.

Sample clamping is straightforward with manual options, and Mikrosize, as a comprehensive Measuring Testing Instrument supplier, can configure hydraulic or pneumatic clamping systems based on user requirements for high-volume or specialized sample testing. Safety is never compromised, with multiple protection measures including over-voltage, over-current, and mechanical limit switches to safeguard both the operator and the equipment.

Why Choose Mikrosize as Your Testing Partner?

Selecting the right Electronic Universal Testing Machine is a critical investment in your quality assurance and R&D capabilities. Mikrosize stands out as a premier supplier by combining robust German-engineered mechanics with intuitive, powerful software. Our machines are designed not just to perform tests, but to deliver the precise, reliable, and actionable data that engineers and scientists need to innovate and ensure product excellence. Whether you are testing metals, polymers, composites, textiles, or geosynthetics, a Mikrosize UTM provides the versatility, accuracy, and user-friendly operation required in a modern laboratory.

For more information on our range of Measuring Testing Instruments and to find the perfect Universal Testing Machine for your application, contact the experts at Mikrosize today. Let us help you unlock the full potential of your materials.