As a leading Measuring Testing Instrument supplier, Mikrosize is committed to delivering high-performance testing equipment for industrial quality control. The Shore D Hardness Tester, a flagship product in Mikrosize’s measuring testing instrument lineup, is engineered with advanced mechatronics integration—blending precision mechanical components with optimized structural design to ensure reliable and consistent hardness measurement across diverse industrial scenarios.

1. Product Introduction

Designed exclusively as a Shore D-type hardness tester, this portable measuring testing instrument is tailored to meet the rigorous hardness testing demands of both ferrous and non-ferrous metals (e.g., alloy steels, aluminum alloys, copper alloys). Beyond metal materials, it excels in measuring the hardness of non-metallic and composite materials, including dense granite (often used in precision machine bases), carbon brushes (critical for electrical equipment performance), high-purity graphite (for industrial electrodes), and metal tungsten carbide (a key material in cutting tools and wear-resistant parts). Notably, it efficiently handles materials with a hardness value not exceeding 115°, covering 90% of common industrial testing scenarios.

Core Structural & Functional Details

Punch Design: The instrument features a high-precision punch (36.2g weight) crafted from wear-resistant alloy steel. Its 1mm spherical tip radius is calibrated to minimize material damage while ensuring deep enough indentation for accurate readings. The fixed 19mm punch drop height—strictly controlled during production—eliminates human error in impact force, a key factor in consistent hardness measurement.

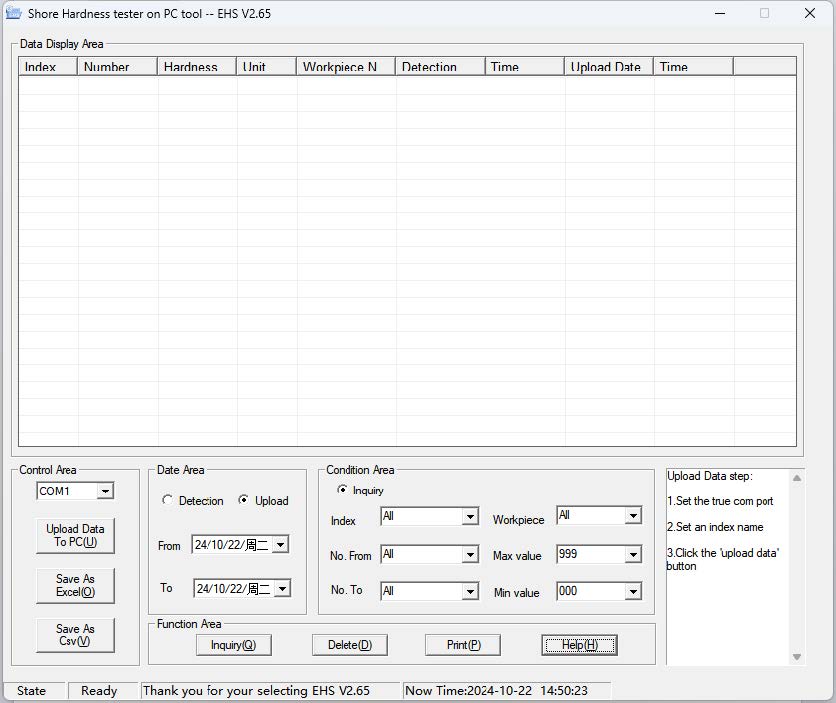

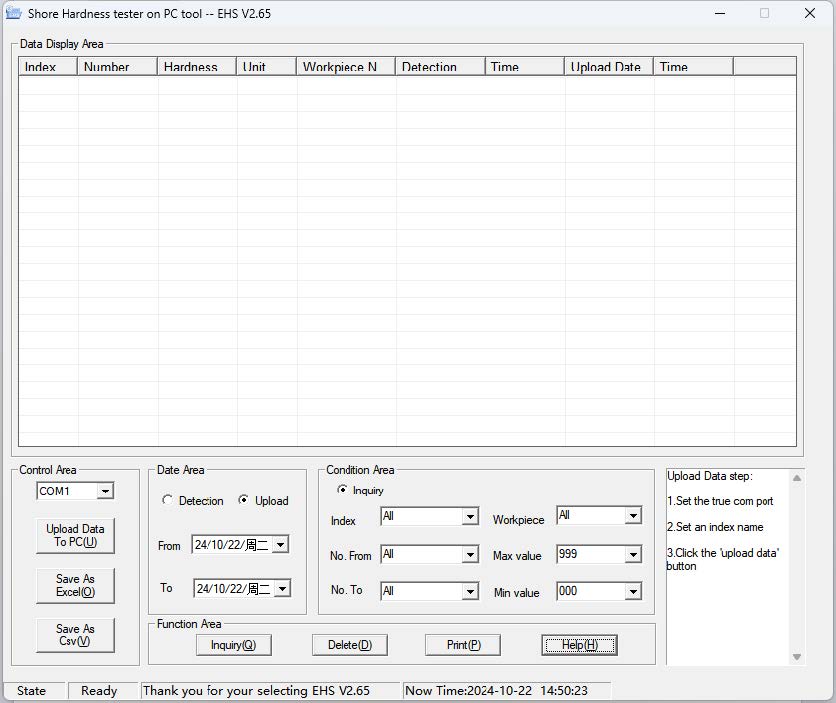

Operational & Data Features: Equipped with an external printer interface, it enables on-site printing of test data (including timestamp, material type, and hardness value) for traceability, a must for ISO-compliant production lines. While it only supports vertical measurement (optimized for flat or slightly curved workpieces), its compact design (150×80×50mm, approx.) and lightweight (≤500g) allow easy operation in tight spaces, such as inside rolling mill frames or alongside large machine tool tracks.

2. Main Features: Engineered for Industrial Practicality

Mikrosize’s Shore D Hardness Tester stands out for its user-centric and industry-adapted features, making it a preferred choice for on-site quality monitoring:

Ultra-Portable & User-Friendly: Its small form factor fits easily into toolkits, and the one-button manual operation (no complex setup) allows operators to master testing in 5 minutes—no specialized electrical or mechanical training required.

Direct Dial Reading with High Clarity: The large, anti-glare dial (diameter 40mm) features clear graduation marks (0-100HSD) and a high-contrast pointer, ensuring readable results even in low-light factory environments (e.g., rolling mill workshops with dim overhead lighting).

All-Mechanical Operation for Reliability: Unlike electric hardness testers that rely on power sources and circuit boards (prone to failure in dusty or vibrating industrial sites), this instrument uses a purely mechanical testing mechanism. It operates independently of electricity, ensuring stable performance in harsh working conditions (temperature range: -10°C to 50°C; relative humidity: ≤85%).

Strong Environmental Adaptability: The outer casing is made of impact-resistant ABS plastic, with a rubberized grip for anti-slip handling. It resists oil stains and minor collisions, making it suitable for on-site testing in rolling mills, machine tool factories, and construction material workshops.

Compliant with National Standards: Its accuracy fully meets the requirements of GB/T 4341 (Metallic Shore Hardness Test Method) and JB/T 8284 (Shore Hardness Tester)—two core national standards for hardness testing in China. Each unit undergoes a 3-step calibration process (using standard hardness blocks) before leaving the factory, ensuring measurement error ≤±2HSD.

3. Application Scope: Targeted for Key Industrial Scenarios

This measuring testing instrument is not just a general-purpose hardness tester; it is optimized for specific high-demand industrial applications:

Metal Material Testing: Accurately measures the Shore hardness of ferrous metals (e.g., quenched steel rollers in rolling mills, cast iron machine tool beds) and non-ferrous metals (e.g., aluminum alloy structural parts, copper alloy electrical connectors). It helps verify whether materials meet the hardness requirements for wear resistance, strength, and durability.

Rolling Mill Industry: Rolling mills rely on steel rollers with precise hardness to ensure uniform thickness of rolled materials (e.g., steel plates, aluminum foils). This tester is used to spot-check roller hardness during production shifts—operators can quickly test multiple points on the roller surface without disassembling the equipment, preventing product defects caused by uneven roller hardness.

Machine Tool Manufacturing: Machine tool tracks (guides) require high hardness to resist wear from repeated sliding of worktables. The tester is used to inspect the hardness of track surfaces during assembly and maintenance, ensuring smooth operation and long service life of machine tools (e.g., lathes, milling machines).

Non-Metal & Composite Material Testing: For granite, it tests the hardness of granite platforms (used for precision measurement and tool calibration) to ensure dimensional stability; for carbon brushes, it checks hardness to avoid excessive wear (if too soft) or commutator damage (if too hard) in motors and generators; for tungsten carbide, it measures hardness to confirm the ability of cutting tools (e.g., drill bits, end mills) to withstand high-speed cutting forces.

4. Main Technical Specifications

The product model of this Shore D-type hardness tester is Mikrosize-SD200. Its measurement range is 20-100HSD, which can cover most industrial materials with a hardness not exceeding 115°. The punch, made of wear-resistant alloy steel, has a weight of 36.2g, and its drop height is fixed at 19mm—this fixed design ensures consistent impact force and reduces human error. The spherical tip radius of the punch is 1mm, which minimizes damage to the tested material while ensuring an indentation depth sufficient for accurate readings. The instrument’s measurement error is ≤±2HSD, achieved through calibration with standard hardness blocks before leaving the factory. It adopts a mechanical manual operation mode, requiring no electricity for use, and supports optional external printer connection for data output, which is conducive to realizing test data traceability. The measurement direction is vertical only, optimized for testing flat or slightly curved workpieces. In terms of size, it has an approximate dimension of 150×80×50mm, and its weight is no more than 500g, making it compact and lightweight for on-site carrying and operation. The applicable operating environment ranges from -10°C to 50°C in temperature, with a relative humidity of ≤85%, enabling stable performance in harsh industrial sites.