Advanced Digital Brinell Hardness Tester: Precision Meets Versatility

The Digital Brinell Hardness Tester, available through Mikrosize and a flagship product of Measuring Testing Instrument, represents the pinnacle of modern hardness testing technology. Engineered for unparalleled accuracy and user convenience in industrial and laboratory settings, this instrument is an indispensable tool for quality control and material science applications. It seamlessly integrates three fundamental testing methodologies—Brinell, Rockwell, and Vickers—into a single, robust platform. This multi-functional capability eliminates the need for multiple dedicated machines, offering exceptional value and flexibility for facilities that handle a wide range of materials, from soft metals to hardened steels and thin coatings.

Unmatched Precision in Measurement and Control

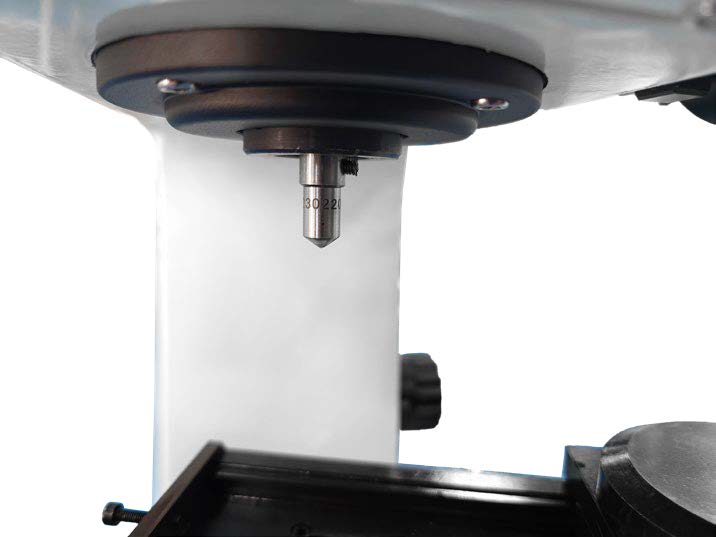

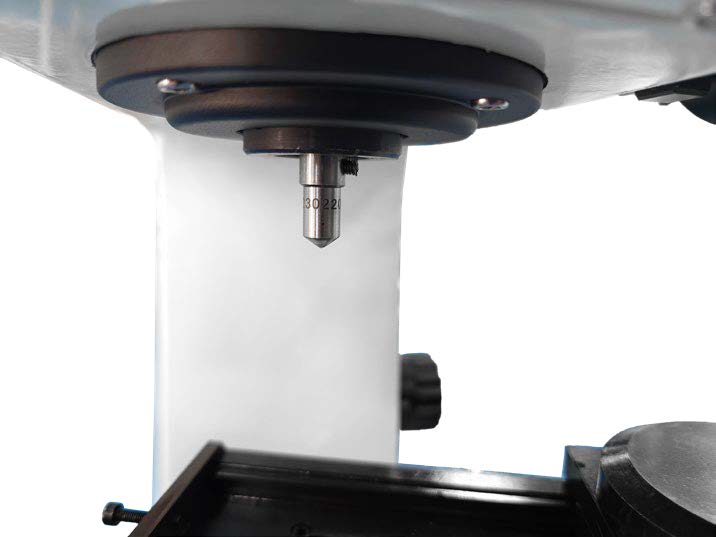

At the heart of the Blowe Hardness Tester lies a commitment to precision. The system is driven by the renowned "Aolongxin" high-precision stepper control system, which ensures exceptionally smooth and stable loading of test forces, critical for repeatable and reliable results. This is complemented by a high-precision force sensor for accurate load application and a advanced magnetic grid displacement sensor that meticulously determines the residual depth of the indentation. For Brinell and Vickers testing, the tester is equipped with a high-precision micrometer eyepiece, allowing for intuitive and highly accurate visual measurement of indentations. The external light source further enhances observation, making the process simpler and reducing operator eye strain.

Intuitive Operation and Comprehensive Data Management

Operation is streamlined through a vibrant 8-inch touch screen, which serves as the central hub for all controls and data display. This intuitive interface simplifies the human-machine dialogue, allowing operators to easily switch between Rockwell, Brinell, and Vickers readings. The system offers an extensive selection of testing scales, including 15 options for Rockwell, 8 for Brinell, and 6 for Vickers, with synchronous switching of the test force scale. Key features like hardness test holding time settings, upper and lower limit value configuration with visual red alerts for out-of-spec results, and sophisticated correction functions for both standard samples and complex geometries like cylinders and spheres, make it a highly intelligent testing solution.

Connectivity, Compliance, and Output

The Digital Blowe Hardness Tester is designed for seamless integration into modern workflow systems. It retains up to 120 test data points in its memory, which can be selectively managed or deleted. For permanent records, the built-in printer provides immediate output of test data and statistical summaries. Furthermore, the standard RS-232 data output interface enables serial communication with external computers for advanced data analysis and long-term storage. To ensure ongoing accuracy, the instrument features segmented correction for Rockwell hardness values and includes built-in HR, HB, and HV conversion scales, simplifying calibration and compliance with international standards. As a premier offering from Measuring Testing Instrument, distributed by Mikrosize, this tester guarantees performance, reliability, and comprehensive support.

Advanced Digital Blowe Hardness Tester: Precision Meets Versatility

The Digital Blowe Hardness Tester, available through Mikrosize and a flagship product of Measuring Testing Instrument, represents the pinnacle of modern hardness testing technology. Engineered for unparalleled accuracy and user convenience in industrial and laboratory settings, this instrument is an indispensable tool for quality control and material science applications. It seamlessly integrates three fundamental testing methodologies—Brinell, Rockwell, and Vickers—into a single, robust platform. This multi-functional capability eliminates the need for multiple dedicated machines, offering exceptional value and flexibility for facilities that handle a wide range of materials, from soft metals to hardened steels and thin coatings.

Unmatched Precision in Measurement and Control

At the heart of the Brinell Hardness Tester lies a commitment to precision. The system is driven by the renowned "Aolongxin" high-precision stepper control system, which ensures exceptionally smooth and stable loading of test forces, critical for repeatable and reliable results. This is complemented by a high-precision force sensor for accurate load application and a advanced magnetic grid displacement sensor that meticulously determines the residual depth of the indentation. For Brinell and Vickers testing, the tester is equipped with a high-precision micrometer eyepiece, allowing for intuitive and highly accurate visual measurement of indentations. The external light source further enhances observation, making the process simpler and reducing operator eye strain.

Intuitive Operation and Comprehensive Data Management

Operation is streamlined through a vibrant 8-inch touch screen, which serves as the central hub for all controls and data display. This intuitive interface simplifies the human-machine dialogue, allowing operators to easily switch between Rockwell, Brinell, and Vickers readings. The system offers an extensive selection of testing scales, including 15 options for Rockwell, 8 for Brinell, and 6 for Vickers, with synchronous switching of the test force scale. Key features like hardness test holding time settings, upper and lower limit value configuration with visual red alerts for out-of-spec results, and sophisticated correction functions for both standard samples and complex geometries like cylinders and spheres, make it a highly intelligent testing solution.

Connectivity, Compliance, and Output

The Digital Brinell Hardness Tester is designed for seamless integration into modern workflow systems. It retains up to 120 test data points in its memory, which can be selectively managed or deleted. For permanent records, the built-in printer provides immediate output of test data and statistical summaries. Furthermore, the standard RS-232 data output interface enables serial communication with external computers for advanced data analysis and long-term storage. To ensure ongoing accuracy, the instrument features segmented correction for Rockwell hardness values and includes built-in HR, HB, and HV conversion scales, simplifying calibration and compliance with international standards. As a premier offering from Measuring Testing Instrument, distributed by Mikrosize, this tester guarantees performance, reliability, and comprehensive support.