Advanced All-Digital Ultrasonic Flaw Detector from Mikrosize

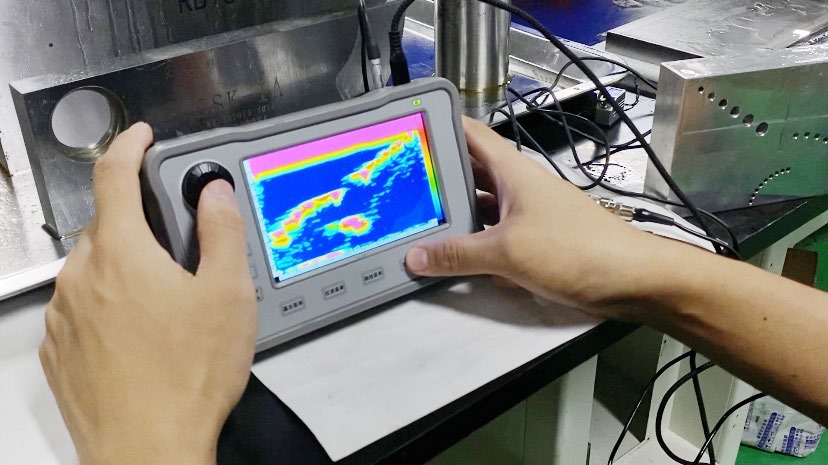

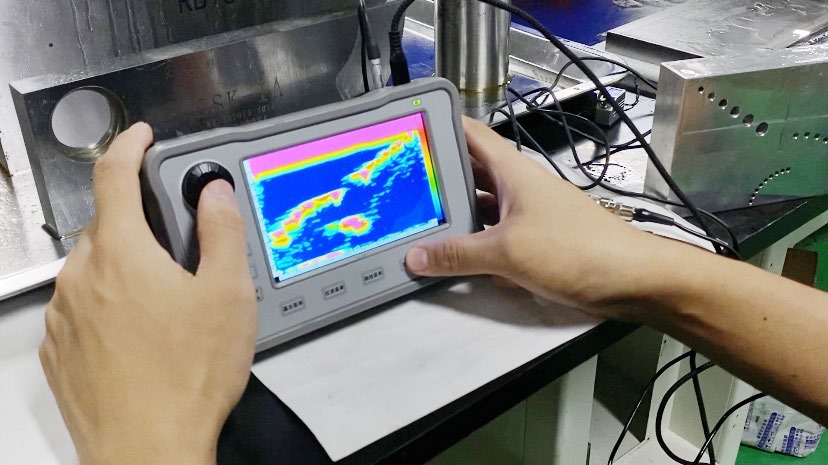

Mikrosize, a renowned supplier of precision measurement solutions, presents a state-of-the-art All-Digital Ultrasonic Flaw Detector, representing the pinnacle of portable non-destructive testing technology. This instrument is engineered for professionals who demand uncompromising accuracy, reliability, and ease of use in the field. Adopting an innovative, ultra-large screen with high brightness display, the device combines an aesthetically pleasing and robust design with a remarkably compact form factor. Despite its small size, it boasts a large, 5-inch high-resolution LCD screen that ensures exceptional clarity in various lighting conditions. As a premier product in the field of Measuring and Testing Instrumentation, it offers powerful functionality, stable performance, and intuitive operation, making it an advanced tool for detecting internal defects such as cracks, inclusions, and porosity with automatic evaluation and diagnostic capabilities.

This versatile flaw detector from Mikrosize is an indispensable Measuring and Testing Instrument across a wide spectrum of industries. Its applications are critical in laboratories, special inpection institutes, and sectors including shipbuilding, oil and gas equipment, aerospace, military, chemical processing, power generation, steel and metallurgy, railways, automotive manufacturing, general machinery, boilers and pressure vessels, special equipment, petroleum pipelines, construction, and mold manufacturing. The instrument’s comprehensive feature set is designed to meet and exceed the rigorous standards of these fields.

Key Features and Capabilities:

The instrument is equipped with an HDMI interface, allowing seamless connection to external displays and projectors for enhanced data analysis, reporting, and collaborative review. For expansive data storage, it features a TF card interface, enabling users to significantly expand their data storage capacity for extensive field campaigns. A sophisticated digital filtering function allows for the precise selection of frequency bands, making it exceptionally suitable for inspecting difficult-to-test workpieces with complex grain structures or challenging geometries.

Weighing only 0.7kg with compact dimensions of 180 x 135 x 40mm, this portable device does not compromise on display or functionality, featuring a 5-inch high-resolution LCD and a universal knob for effortless operation. It supports dynamic continuous storage and comes with 5 built-in detection standards, streamlining the setup process. The advanced echo envelope function provides excellent analysis of defect categories by capturing the peak signal response. Furthermore, the instrument automates the calibration of essential parameters such as material sound velocity, probe delay, and probe K value, reducing operator error and saving valuable time.

The creation and application of DAC (Distance Amplitude Correction) and AVG (DGS - Distance Gain Size) curves are highly streamlined. The DAC curve functionality is embedded with both domestic and international standards, including ASME, ASME III, JIS, EN1712, GB/T11345, and NB/T47013.3, and allows users to customize up to 7 DAC curve parameters for rapid selection. A unique DAC curve sensitivity query table function is included, which is particularly convenient for training purposes and for filling out inspection reports. The software is designed with an intuitive operation process and automatic parameter adjustment, enabling even beginners to quickly master basic flaw detection methodologies.

Designed in compliance with the European standard EN12668-1:2010, this Mikrosize instrument ensures high quality and reliability. It incorporates multiple advanced detection modules: a continuous storage function module that records the entire waveform during the scanning process, ideal for data analysis and teaching demonstrations; a B-scan function module for rapid corrosion thickness assessment; and a dedicated AWS D1.1 professional module tailored for the detection and evaluation of steel structure welds.

With 50 independent flaw detection channels (expandable for more complex applications), the device provides comprehensive testing flexibility. It offers real-time display of all critical defect echo parameters, including distance, horizontal and vertical position, amplitude, dB equivalent, and aperture value. During automatic calibration of the probe zero point, K-value, and the creation of DAC/AVG curves, the instrument intelligently records the highest wave and automatically draws the envelope for precise analysis. The DAC and AVG curves are not limited in their production sampling points and can be compensated and corrected, with the DAC curve automatically adjusting with gain changes.

With a maximum sampling rate of 240MHz and a measurement resolution of 0.01mm, the detector captures minute details with high precision. It includes powerful functions such as peak memory, waveform freezing, and dual alarm gates. Data integrity is ensured by large-capacity internal storage for over 3000 inspection records, with all data protected from loss after power failure. To optimize performance for any application, the filtering frequency band and probe damping are fully adjustable. The alarm gates for incoming and lost waves are fully configurable, with continuously adjustable position, width, and height. High-reliability data protection ensures stored information is secure, and the instrument can directly connect to a printer to generate professional inspection reports.

Strong data processing capabilities allow for efficient searching and management of data by date, workpiece number, and serial number. The instrument can easily communicate with computers for comprehensive data management and backup. Designed for extended field use, it features low power consumption, enabling continuous operation for over three hours, and includes a low-battery alarm. Its robust design ensures the screen remains clear and legible, adapting to all operating environments. As a leading Measuring and Testing Instrument from supplier Mikrosize, this ultrasonic flaw detector sets a new benchmark for portability, power, and precision in non-destructive testing.