As a high-quality Measuring Testing Instrument, the single column electronic universal testing machine plays a crucial role in various industries where the mechanical properties of materials need to be accurately evaluated. This advanced testing equipment is not only designed to meet the diverse testing needs of different materials but also backed by reliable support from professional suppliers like Mikrosize; Mikrosize, a trusted name in the field of testing instruments, ensures that this single column electronic universal testing machine adheres to the highest standards of quality and performance, making it a preferred choice for businesses and research institutions worldwide.

As an essential Measuring Testing Instrument, the single column electronic universal testing machine is highly suitable for testing the mechanical properties of a wide range of materials, including but not limited to metal, rubber, plastic, aluminum-plastic pipes, composite materials, waterproof materials, textiles, yarns, fibers, wires and cables, paper, springs, wood, packaging materials, and tape. It can conduct various types of tests such as tensile, compressive, bending, shear, tearing, and peeling tests, providing comprehensive data on material performance. What sets this Measuring Testing Instrument apart is its advanced 4000 control series, which enables the achievement of multi closed-loop tests like constant stress, constant strain, creep, and relaxation tests, expanding the scope of applications for the machine. Moreover, in line with international standards such as GB, JIS, ASTM, and DIN, this testing machine can automatically calculate a variety of important parameters—including tensile strength, yield strength, elongation, tensile stress (a key parameter for multiple material evaluations, hence repeated), and spring modulus. This automatic calculation function not only saves time and effort but also ensures the accuracy and consistency of test results, a feature that Mikrosize emphasizes to meet the strict requirements of users in different fields.

The single column structure of this Measuring Testing Instrument is not only beautiful and exquisite but also designed for sitting operation, ensuring that operators can work in an easy and natural posture; this humanized design reduces operator fatigue during long-term testing processes, improving work efficiency, and Mikrosize pays great attention to such user-friendly details in the production of this testing machine, aiming to provide a comfortable and efficient testing experience. One of the outstanding advantages of this single column electronic universal testing machine is its high measurement accuracy, with experimental measurement accuracy reaching level 0.5—a significant indicator of its reliability as a Measuring Testing Instrument. This high accuracy ensures that even the smallest changes in material properties during testing can be accurately detected, providing valuable data for material research and quality control, and with the strict quality control measures implemented by Mikrosize, this high measurement accuracy is consistently maintained. The sampling rate of this testing machine is up to 200 times per second, allowing it to capture real-time data during the testing process and ensure no important information is missed—critical for dynamic tests where material properties change rapidly—and as a professional supplier, Mikrosize ensures that the sampling system of this Measuring Testing Instrument is highly stable and responsive, meeting the needs of high-speed testing scenarios.

Equipped with the Rigel fully digital control system, this Measuring Testing Instrument is combined with a complete set of imported AC servo systems and motors, a combination that completely eliminates displacement drift (a common issue in many testing machines that can affect test accuracy). The advanced control system ensures precise control of the testing process, allowing for accurate adjustment of test parameters such as speed and force, and Mikrosize selects high-quality components for the control system to guarantee its long-term stability and reliable performance. The circular toothed synchronous belt reduction system of this testing machine adopts a pure digital phase-locked loop position pulse control mode, offering benefits like no zero drift, no misalignment, low noise, high efficiency, and smooth transmission—features that contribute to the overall stability and accuracy of the testing machine, making it a reliable Measuring Testing Instrument—and Mikrosize conducts rigorous testing on this reduction system to ensure it can withstand long-term use and maintain excellent performance. Using high-precision ball screw loading, the testing machine achieves smooth loading, which not only ensures the accuracy of test results but also extends the machine’s service life; additionally, this loading mechanism provides good long-term stability and energy-saving effects (important considerations for users in terms of operational costs and environmental protection), and Mikrosize prioritizes the use of high-quality ball screws to ensure the superior performance of this loading mechanism.

Displacement measurement of this Measuring Testing Instrument is carried out using an imported photoelectric encoder, ensuring no misalignment and no drift, with a minimum resolution of 1μm—allowing for extremely precise measurement of material displacement during testing. This high level of accuracy in displacement measurement is crucial for evaluating the deformation characteristics of materials, making the machine a top-tier Measuring Testing Instrument, and Mikrosize sources high-quality imported photoelectric encoders to ensure the accuracy and reliability of displacement measurement. This single column electronic universal testing machine also has multiple sub-channels, enabling true extended measurement with multiple sensors; this multi-channel capability allows for simultaneous measurement of different load and deformation parameters, providing a more comprehensive understanding of material performance and enhancing the machine’s flexibility (as it can be adapted to different testing configurations based on specific user needs)—and Mikrosize ensures the multi-channel system is well-integrated and calibrated to provide accurate and consistent measurement results. The large deformation measurement function of this Measuring Testing Instrument features automatic tracking and precise measurement, meeting international standards—particularly important for testing materials that undergo significant deformation before failure, such as rubber and textiles—and the automatic tracking feature ensures the measurement system keeps up with the material’s deformation, providing accurate data throughout the testing process; Mikrosize validates this function against international standards to ensure compliance and accuracy.

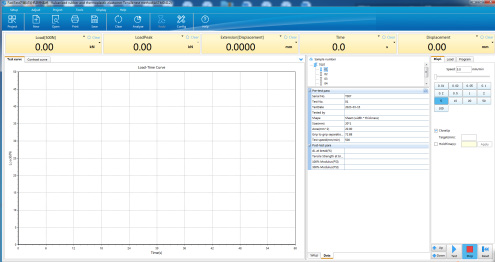

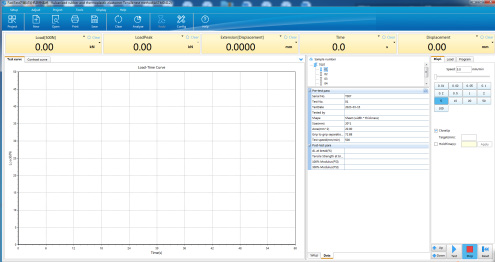

The test speed range of this testing machine reaches 3 million times, making it highly versatile—it can adapt to both high-speed tests (such as those required for certain metal materials) and low-speed tests (such as creep tests for polymers), expanding the machine’s application areas to meet the testing needs of various materials and industries—and Mikrosize optimizes the speed control system to ensure smooth and stable operation across the entire speed range. The single column electronic universal testing machine is also equipped with multiple safety protection functions, including mechanical, electrical, and software protection; mechanical protection includes limit switches and protective covers, electrical protection involves overload and short-circuit protection, and software protection features alarm systems and emergency stop functions—all working together to ensure the safety of operators and the integrity of the machine during operation—and Mikrosize places great importance on safety, ensuring all these protection functions are thoroughly tested and reliable. The user interface of this Measuring Testing Instrument is simple, reliable, and powerful; designed to be intuitive, it allows operators to easily set up test parameters, start/stop tests, and view results, while its powerful software also includes data analysis and reporting functions—making it easy for users to process and present test data—and Mikrosize continuously improves the user interface based on user feedback to enhance usability and experience.

An open data structure is a key feature of this testing machine, allowing users to randomly access both result parameters and process data—highly beneficial for scientific research and teaching, as researchers and students can analyze the testing process in detail and conduct in-depth studies on material performance. The user self-editing report function enables customization of test reports according to specific requirements, and data can be easily imported into an Excel spreadsheet for convenient later processing and analysis; Mikrosize ensures the data structure is compatible with common software applications, making data sharing and processing more convenient. To meet the different testing requirements of various users, this Measuring Testing Instrument offers hundreds of different fixtures and accessories, designed to accommodate different types of materials and test methods—ensuring the machine can be used for a wide range of applications, whether testing the tensile strength of a metal wire or the peeling strength of a tape—and Mikrosize provides a comprehensive range of these fixtures and accessories, as well as customization services to meet specific user needs.

In conclusion, the single column electronic universal testing machine, as a high-performance Measuring Testing Instrument, offers exceptional functionality, accuracy, and versatility. With the support of Mikrosize as a reliable supplier, this testing machine is well-equipped to meet the diverse testing needs of industries such as manufacturing, research, and education, and its advanced features and user-friendly design make it an indispensable tool for evaluating the mechanical properties of materials and ensuring product quality.