- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

- Home

- About Us

- Products

- Case

- Service

- News

- Download

- Contact Us

Views: 0 Author: Site Editor Publish Time: 2025-10-30 Origin: Site

Digital Micro Vickers Hardness Tester: Precision Meets Innovation

The Digital Micro Vickers Hardness Tester represents the forefront of material testing technology, designed for unparalleled accuracy and user convenience. This advanced instrument is engineered to deliver reliable microhardness measurements for a wide array of industrial and research applications. Its development is a testament to the expertise of its supplier, Mikrosize, a name synonymous with precision and quality in the field of metrology. As a prominent Measuring Testing Instrument, this hardness tester integrates sophisticated optical systems, robust mechanical construction, and intelligent digital controls to meet the rigorous demands of modern quality control laboratories.

Product Features: A Blend of Optical Clarity and Mechanical Excellence

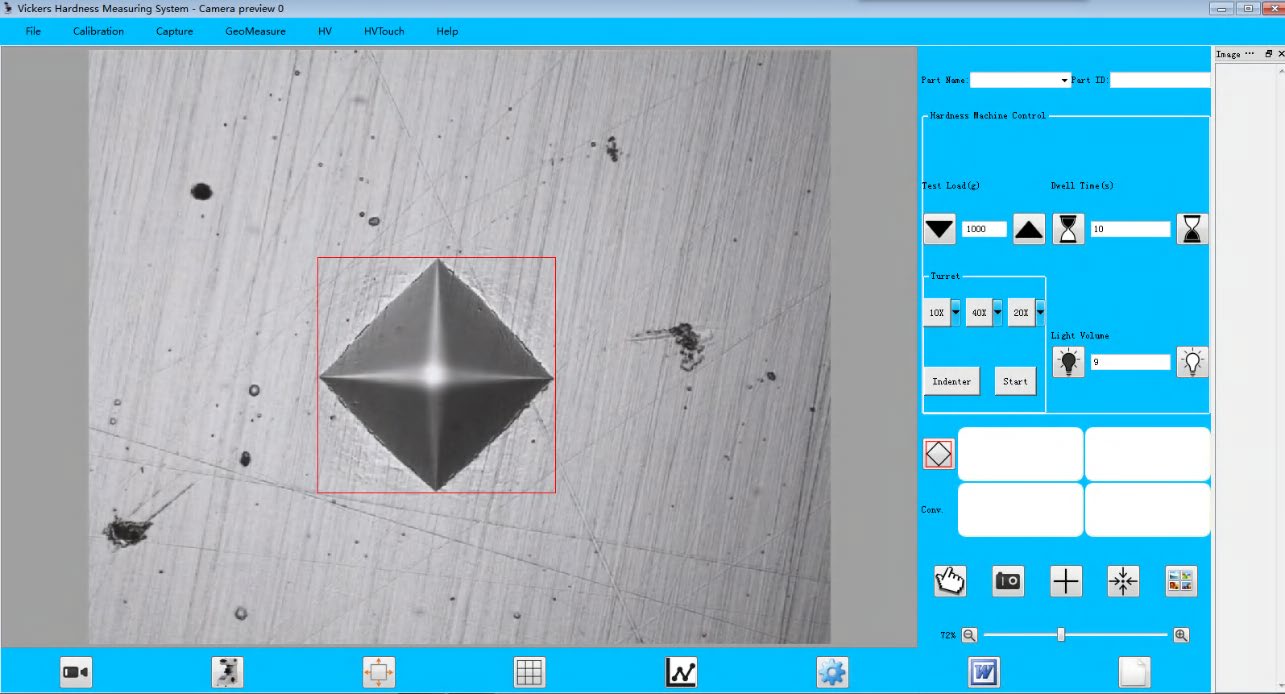

A standout feature of this tester is its superior optical system, which provides exceptionally clear image quality and high-definition display. The capability for measurement through both lenses significantly broadens its application scope, allowing for precise indentation observation across various materials. The system employs an optical cross guide rail guidance mechanism, ensuring superior guidance accuracy and long-term stability. Furthermore, the innovative two-stage gear rack force transmission system facilitates both fast and remarkably smooth force application, enhancing testing efficiency. At the heart of its force application is a high transmission ratio, high-precision worm gear mechanism. This design guarantees more precise force transmission, resulting in measurements that are consistently accurate and reliable, a crucial aspect for any high-end Measuring Testing Instrument.

Modern User Interface and Compliance

Embracing modern ergonomics, the tester is equipped with a large touch screen LCD display. This interface revolutionizes user interaction by replacing traditional push-button screens with intuitive screen touch operations, streamlining the testing workflow and minimizing operator error. Manufactured by Shanghai Yizong Precision Instrument Co., Ltd. and supplied by Mikrosize, this instrument is built to conform with major international standards, including Chinese National Standard GB/T 4340.2, International Standard ISO 6507, and American Standard ASTM-E92. This compliance ensures that test results are recognized and valid across global markets.

Comprehensive Scope of Application

The versatility of this Digital Micro Vickers Hardness Tester makes it an indispensable tool in numerous sectors. It is perfectly suited for the microhardness measurement of parts that have undergone various surface treatments such as heat treatment, carburization, nitriding, and carbonitriding. It is also extensively used for evaluating the hard anodized layer and quenched hardened layer on aluminum alloys. Beyond these, its applications extend to testing surface coatings, stainless steel, non-ferrous metals, thin materials like copper strips and aluminum foils, as well as small and thin parts that would be challenging to measure with other methods. As a versatile Measuring Testing Instrument, it provides critical data for quality assurance and material research.

Detailed Product Description

The digital micro Vickers hardness tester from Shanghai Yizong Precision Instrument Co., Ltd., supplied by Mikrosize, is a state-of-the-art large touch screen digital micro hardness tester. It features an expansive 8-inch touch screen for comprehensive control and display, supporting bilingual operation in both Chinese and English to cater to a global user base. This instrument is specifically designed for measuring the hardness of precision mechanical parts, including hard alloys, various grades of steel, metal structures, and their surface processing layers. It is equally effective for testing electroplating layers, nitriding layers, carburizing layers, and cyanide layers. The surface hardness of small, delicate parts and brittle materials like ceramics can be measured with minimal surface damage.

To further enhance its capability, users have the option to integrate specialized micro Vickers image measurement software. This powerful add-on automates the measurement process, eliminating the need for manual observation through the microscope. Hardness values and analysis curves are displayed clearly and in real-time on the computer monitor, facilitating easy data interpretation and record-keeping. The system also includes the practical functionality of automatic conversion to commonly used hardness scales like Rockwell and Brinell. Renowned for its ease of use, reliable measurement data, and stable performance, this Measuring Testing Instrument from Mikrosize is a trusted solution for ensuring material quality and advancing scientific understanding.

Digital Micro Vickers Hardness Tester: Precision Meets Innovation

The Digital Micro Vickers Hardness Tester represents the forefront of material testing technology, designed for unparalleled accuracy and user convenience. This advanced instrument is engineered to deliver reliable microhardness measurements for a wide array of industrial and research applications. Its development is a testament to the expertise of its supplier, Mikrosize, a name synonymous with precision and quality in the field of metrology. As a prominent Measuring Testing Instrument, this hardness tester integrates sophisticated optical systems, robust mechanical construction, and intelligent digital controls to meet the rigorous demands of modern quality control laboratories.

Product Features: A Blend of Optical Clarity and Mechanical Excellence

A standout feature of this tester is its superior optical system, which provides exceptionally clear image quality and high-definition display. The capability for measurement through both lenses significantly broadens its application scope, allowing for precise indentation observation across various materials. The system employs an optical cross guide rail guidance mechanism, ensuring superior guidance accuracy and long-term stability. Furthermore, the innovative two-stage gear rack force transmission system facilitates both fast and remarkably smooth force application, enhancing testing efficiency. At the heart of its force application is a high transmission ratio, high-precision worm gear mechanism. This design guarantees more precise force transmission, resulting in measurements that are consistently accurate and reliable, a crucial aspect for any high-end Measuring Testing Instrument.

Modern User Interface and Compliance

Embracing modern ergonomics, the tester is equipped with a large touch screen LCD display. This interface revolutionizes user interaction by replacing traditional push-button screens with intuitive screen touch operations, streamlining the testing workflow and minimizing operator error. Manufactured by Shanghai Yizong Precision Instrument Co., Ltd. and supplied by Mikrosize, this instrument is built to conform with major international standards, including Chinese National Standard GB/T 4340.2, International Standard ISO 6507, and American Standard ASTM-E92. This compliance ensures that test results are recognized and valid across global markets.

Comprehensive Scope of Application

The versatility of this Digital Micro Vickers Hardness Tester makes it an indispensable tool in numerous sectors. It is perfectly suited for the microhardness measurement of parts that have undergone various surface treatments such as heat treatment, carburization, nitriding, and carbonitriding. It is also extensively used for evaluating the hard anodized layer and quenched hardened layer on aluminum alloys. Beyond these, its applications extend to testing surface coatings, stainless steel, non-ferrous metals, thin materials like copper strips and aluminum foils, as well as small and thin parts that would be challenging to measure with other methods. As a versatile Measuring Testing Instrument, it provides critical data for quality assurance and material research.

Detailed Product Description

The digital micro Vickers hardness tester from Shanghai Yizong Precision Instrument Co., Ltd., supplied by Mikrosize, is a state-of-the-art large touch screen digital micro hardness tester. It features an expansive 8-inch touch screen for comprehensive control and display, supporting bilingual operation in both Chinese and English to cater to a global user base. This instrument is specifically designed for measuring the hardness of precision mechanical parts, including hard alloys, various grades of steel, metal structures, and their surface processing layers. It is equally effective for testing electroplating layers, nitriding layers, carburizing layers, and cyanide layers. The surface hardness of small, delicate parts and brittle materials like ceramics can be measured with minimal surface damage.

To further enhance its capability, users have the option to integrate specialized micro Vickers image measurement software. This powerful add-on automates the measurement process, eliminating the need for manual observation through the microscope. Hardness values and analysis curves are displayed clearly and in real-time on the computer monitor, facilitating easy data interpretation and record-keeping. The system also includes the practical functionality of automatic conversion to commonly used hardness scales like Rockwell and Brinell. Renowned for its ease of use, reliable measurement data, and stable performance, this Measuring Testing Instrument from Mikrosize is a trusted solution for ensuring material quality and advancing scientific understanding.