In the field of industrial inspection, a detection device that is highly performant, easy to operate and adaptable to multiple scenarios often brings great convenience to production, maintenance and other links. The iLeeb-300 Leeb hardness tester is such a detection device that combines strength and practicality. Whether it is the hardware structure design, core performance, or rich application scenarios, it all demonstrates outstanding advantages and has become a capable assistant in the inspection work of many industries.

From the perspective of hardware structure, the iLeeb-300 Leeb hardness tester is designed with clarity and intuitiveness, making operation simple and easy to understand. The main unit is equipped with key components such as an impact device interface, a color LCD screen, and a keypad. The impact device consists of a release button, a loading sleeve, and other parts, with each component having a clear division of labor and smooth coordination. The color LCD screen is powerful and can simultaneously display 10 key contents such as time and measured values, allowing inspectors to grasp the inspection information in real time and comprehensively. The 9 keys on the keypad correspond to practical functions such as material selection and data storage, eliminating the need for complex operation procedures. Novices can quickly get started, significantly lowering the operation threshold.

In terms of performance, the iLeeb-300 Leeb hardness tester demonstrates industry-leading standards. It is equipped with a Cortex-M4 core processor, which has an extremely fast computing speed and can quickly complete a series of tasks such as hardness value calculation, effectively enhancing the detection efficiency. The probe adopts automatic identification plug-and-play technology, eliminating the need for insertion and removal operations before startup, simplifying the preparation process before detection and saving valuable time. What's more, the main interface of the device can simultaneously display hardness values in all scales such as Leeb and Brinell, eliminating the need for frequent interface switching and making the comparison of detection data more intuitive. At the same time, it supports impact waveform analysis, which further ensures the accuracy of detection data through detailed analysis of the impact process, providing reliable data support for subsequent judgment and decision-making.

In terms of data management, the iLeeb-300 Leeb hardness tester is flexible and efficient. It supports data transmission to a computer via USB communication, facilitating subsequent data organization, analysis, and archiving. Additionally, it features Bluetooth printing, allowing for on-site report output and immediate access to test results without the need for data transfer back and forth. The device can store up to 100 groups of data, meeting the requirements for batch testing data storage. It also offers three viewing modes: data, graphics, and tables, enabling testers to select the most suitable mode based on their needs, making data management and analysis effortless and convenient. Moreover, the device stands out for its battery life and portability. It operates for approximately 50 hours on just two AA alkaline batteries, eliminating the need for a fixed power source. The compact and lightweight design makes it easy to carry, allowing for testing in various environments such as factory workshops, outdoor sites, or confined spaces.

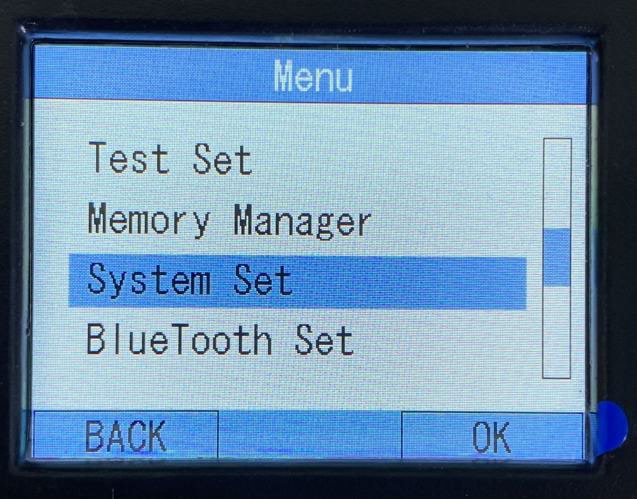

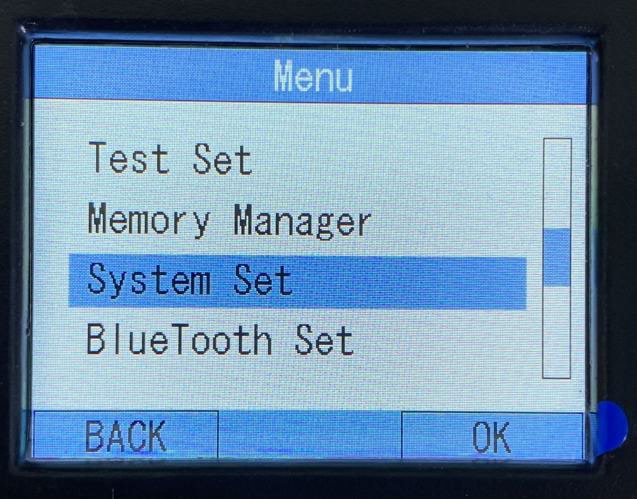

The wide range of applications is another highlight of the iLeeb-300 Leeb hardness tester. It can test various common metal materials such as steel, cast steel, and aluminum alloy, with a measuring range of 170 to 960 HLD. It also supports multi-directional measurements including vertical downward, meeting the testing requirements of various scenarios such as mold cavities, pressure vessels, heavy workpieces, and workpieces in narrow spaces. It can also assist in material differentiation and inventory management. To further enhance the adaptability of the equipment, the iLeeb-300 Leeb hardness tester provides four types of setting functions: test conditions, storage management, system, and Bluetooth. Testers can flexibly adjust parameters according to actual testing needs. The standard configuration is complete, and it also supports optional accessories such as special-shaped impact devices, which can be functionally expanded according to different testing scenarios and requirements, further expanding the application range of the equipment.

In practical application scenarios, the iLeeb-300 Leeb hardness tester plays a significant role with its outstanding performance. In the field of hardness testing for precision parts, it can precisely measure the hardness of critical components such as mold cavities and bearings, and determine whether the parts meet the processing standards by measuring hardness values in various scales. This ensures the stability of the parts' performance in subsequent production or assembly processes and effectively avoids product quality issues caused by substandard hardness. For failure analysis of large-scale equipment, this device can conduct hardness tests on key parts of large-scale equipment such as pressure vessels and steam turbine generator sets without disassembling the equipment. It can quickly identify problems such as material aging, wear, or damage, providing reliable data support for equipment maintenance and fault diagnosis, significantly reducing equipment downtime for maintenance and minimizing economic losses for enterprises.

The iLeeb-300 Leeb hardness tester also performs exceptionally well in the inspection of heavy and installed workpieces. It can complete hardness testing without disassembling the workpiece, thus avoiding damage to the workpiece or equipment during the disassembly process. At the same time, it can conduct large-scale multi-point rapid testing on large workpieces, significantly improving testing efficiency and meeting the needs of batch screening. In special space workpiece inspection scenarios, such as the interior of pipes and narrow gaps between equipment where the testing space is limited, the compact size of the device (150 mm × 76 mm × 37 mm) and the flexible probe design offer significant advantages. It can easily reach these special areas to complete the inspection, perfectly solving the problem that conventional large-scale testing equipment cannot adapt to narrow spaces.

In the work of metal material classification and material management, the iLeeb-300 Leeb hardness tester can also play a significant role. It can conduct rapid hardness tests on raw materials in metal material warehouses. By taking advantage of the hardness characteristic differences of various materials (such as steel, cast aluminum, copper alloys, etc.), it assists staff in accurately distinguishing different raw materials, ensuring the accuracy of material classification and storage, and effectively enhancing the efficiency and precision of warehouse material management. Moreover, whether it is the random inspection of batch workpieces in factory workshops or the detection of workpieces in outdoor environments without external power supply, the device's long battery life (about 50 hours of continuous operation with 2 AA alkaline batteries) and portability (weighing only 245 g) can perfectly adapt. It can quickly obtain test data and support on-site report printing, easily meeting the rapid inspection needs in various scenarios.

In conclusion, the iLeeb-300 Leeb hardness tester has become an outstanding piece of equipment in the industrial inspection field, thanks to its clear and intuitive hardware design, powerful and stable core performance, flexible and efficient data management capabilities, and wide adaptability to various scenarios. It not only provides precise and efficient inspection services for various inspection tasks but also can be flexibly adjusted according to the needs of different industries and scenarios, safeguarding the production, maintenance, and management processes of enterprises, and helping them enhance work efficiency and product quality. It is undoubtedly a multi-scenario inspection tool.