Core Concept Breakdown

First, let's break down the name:

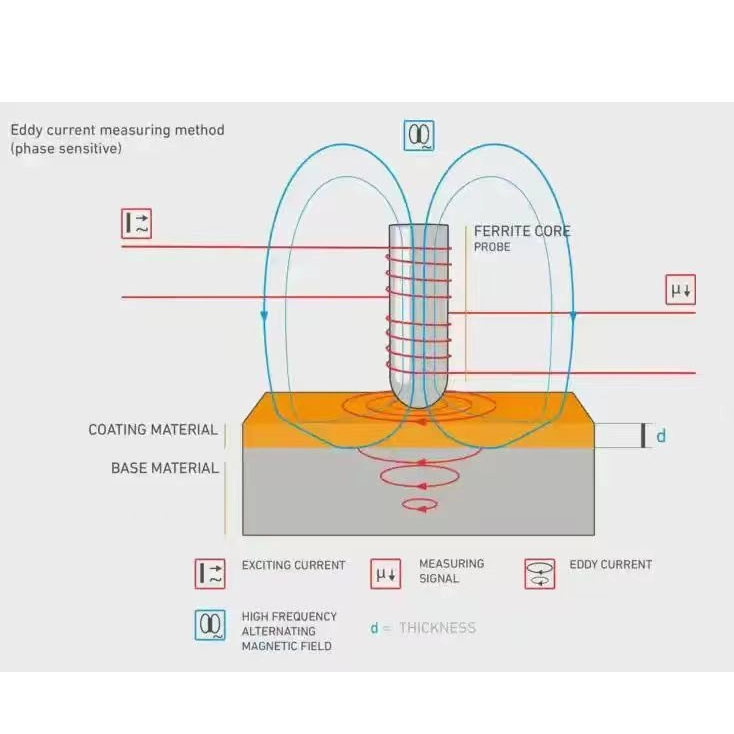

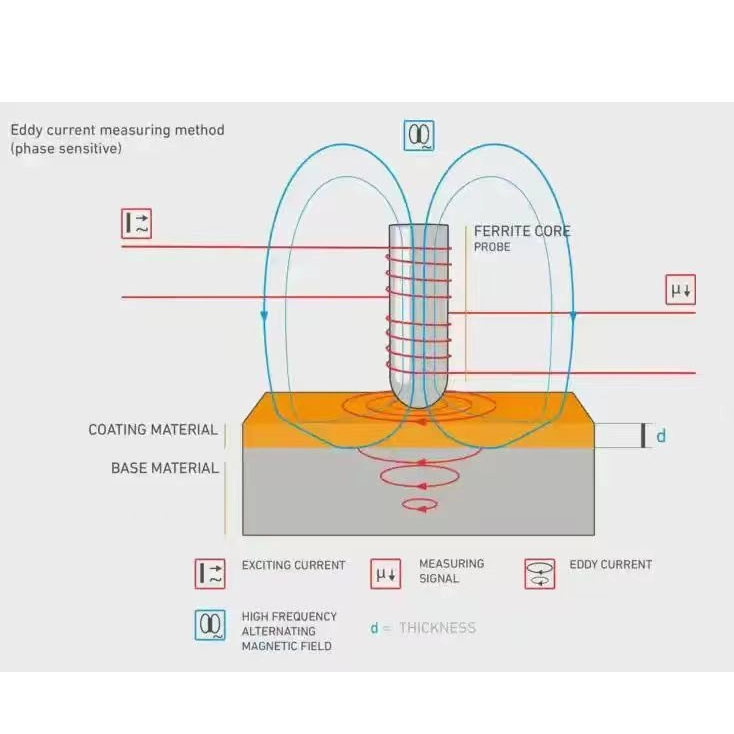

Eddy Current: Refers to the swirling currents induced inside a conductive material (like metal) when an alternating current-carrying coil is brought near it. This is the fundamental physical principle of the technology.

Thickess Gauge: Its primary function is to measure thickness. It is commonly used to measure the thickness of non-conductive coatings (such as paint, ceramic, anodized film, plastic) on a metal substrate, or the thickness of thin metal sheets.

Phae-Sensitive: This is the key and essence of this technology. It means the instrument not only analyzes the amplitude (strength) of the eddy current signal but, more importantly, focuses on analyzing its phase (time delay).

Working Principle

Traditional eddy current thickness gauges primarily rely on measuring changes in the amplitude of the eddy current signal. When the distance between the coil and the metal substrate (i.e., the coating thickness) changes, the amplitude of the eddy current varies. However, the amplitude signal is susceptible to interference from various factors, such as changes in the electrical conductivity and magnetic permeability of the metal substrate, temperature fluctuations, and instrument lift-off effects, leading to inaccurate measurements.

Phase-sensitive technology cleverly solves these problems by introducing phase analysis:

Generation of Two Signal Components:

When the probe (containing the coil) is placed on a coated sample, the impedance in the probe changes.

This impedance change can be decomposed into two mutually perpendicular components: the Resistive Component (R) and the Reactive Component (X). On a vector diagram, these two components form a vector, the magnitude and phase angle of which can be measured.

Relationship Between Phase and Thickness:

Research has shown that the phase angle of the eddy current signal has a very stable and linear relationship with the distance from the probe to the metal substrate (i.e., the coating thickness).

Increased thickness → Phase angle increases proportionally.

More importantly, the phase angle is far less affected by changes in substrate material properties (like conductivity, permeability) than the amplitude signal.

How "Phase-Sensitive" Measurement Works:

The internal circuitry of a phase-sensitive eddy current thickness gauge is specifically designed to accurately measure this phase angle.

The instrument is calibrated to establish a correlation curve between "phase angle" and "thickness".

During actual measurement, the instrument reads the current phase angle and then directly converts it into coating thickness using the built-in calibration curve.

Main Advantages

Compared to traditional amplitude-based eddy current thickness gauges, phase-sensitive technology offers significant advantages:

High Accuracy and Repeatability: Due to the extreme sensitivity and stability of the phase signal to distance changes, the measurement results are very precise and reliable.

Less Affected by Substrate Material: For the same type of metal, even with slight variations in electrical conductivity caused by differences in alloy composition or heat treatment state, the phase method can effectively compensate, reducing measurement errors.

Wider Measurement Range: Can achieve a broad measurement range from a few micrometers to several millimeters.

Better Adaptation to Edge Effect: Performs better than traditional methods when measuring near the edges of a workpiece.

Ability to Distinguish Different Coating Types: Under specific conditions, by analyzing the combined information of phase and amplitude, it can distinguish between different types of non-conductive coatings.

Application Areas

Phase-sensitive eddy current thickness gauges are widely used in applications requiring high-precision, non-contact measurement of non-conductive coating thickness:

Aerospace: Measuring the thickness of paint and anti-corrosion layers on aircraft skins.

Automotive Manufacturing: Measuring paint film thickness on automobile body panels.

Aluminum Profile Industry: Measuring the thickness of anodized films and fluorocarbon spray coatings.

Home Appliance Industry: Measuring the thickness of powder coatings and paint on enclosures.

Research and Quality Control Laboratories: Used for precise measurement in material research and quality control.

Limitations

Only Suitable for Non-Conductive Coatings: Can only measure the thickness of insulating coatings on conductive (metal) substrates. It cannot measure the thickness of conductive coatings (such as electroplated chromium, copper). (For such cases, other techniques based on the eddy current principle or magnetic thickness gauges are required.)

Requires Substrate Calibration: Must be calibrated using standard shims of known thickness and the same material as the workpiece before measurement.

Substrate Thickness Requirement: The metal substrate must be sufficiently thick, greater than the "penetration depth" of the eddy current, otherwise, the measurement will be affected by the backside of the substrate.

Curvature Influence: The probe needs good coupling with the measurement surface. Strongly curved surfaces may affect accuracy, potentially requiring special probes or curvature compensation.

Summary

The phase-sensitive eddy current thickness gauge is an advanced instrument that utilizes the stable relationship between the phase of the eddy current signal and the distance from the probe to the metal substrate to achieve high-precision measurement of non-conductive coating thickness. Its core "phase-sensitive" technology allows it to overcome many shortcomings of traditional amplitude-based methods, playing an indispensable role in the field of industrial quality control and non-destructive testing.