Introduction to Hardness Testing

Hardness is one of the most critical indicators of material mechanical properties, as it directly reflects a material's ability to resist indentation, scratching, or permanent deformation under external pressure. Hardness testing thus serves as an indispensable means for judging the quality of metal materials, product parts, and even some structural components. Specifically, hardness refers to the material's intrinsic capacity to withstand the pressure of another object without undergoing residual deformation— the stronger this resistance, the higher the material's hardness. The Brinell hardness test, in particular, is widely favored for its reliability in hardness determination of materials such as cast iron, carbon steel, alloy steel, non-ferrous metals (like copper and aluminum alloys), and soft alloys. Beyond metals, it also finds application in testing certain non-metallic materials with sufficient hardness, such as hard plastics, bakelite, and some composite materials. This versatility makes it suitable for a wide range of settings, including production factories, processing workshops, quality inspection laboratories, university teaching labs, and scientific research institutions.

The Digital Brinell Hardness Tester: An Overview

The digital Brinell hardness tester, a cutting-edge product supplied by Mikrosize—a globally recognized professional provider of one-stop testing and measuring solutions—stands as a core equipment in the Measuring Testing Instrument field. Mikrosize has long been committed to developing and supplying high-precision testing instruments, and this digital Brinell hardness tester is a testament to its expertise, designed to meet the growing demand for efficient, accurate, and intelligent hardness assessment in modern industrial and research scenarios. It integrates advanced electronic technology and precision mechanical design to simplify complex testing procedures while ensuring consistent and reliable results.

Outstanding Advantages

- Automated Control: Adopts a state-of-the-art fully automatic electronic closed-loop pressure sensor control system, which not only realizes seamless automation of the entire testing process (including loading of test force, holding of force for a preset duration, and unloading of force) but also ensures precise control of each stage. This automation eliminates human errors caused by manual operation, improves testing efficiency, and guarantees the repeatability of test results.

- Stable & Stylish: The product body is manufactured using high-quality precision casting technology, which enhances the overall structural rigidity and stability. This robust construction effectively reduces external vibrations and environmental interference during testing, ensuring the accuracy of measurement data. Meanwhile, the streamlined and atmospheric appearance design makes it not only a functional testing tool but also a neat addition to any laboratory or workshop environment.

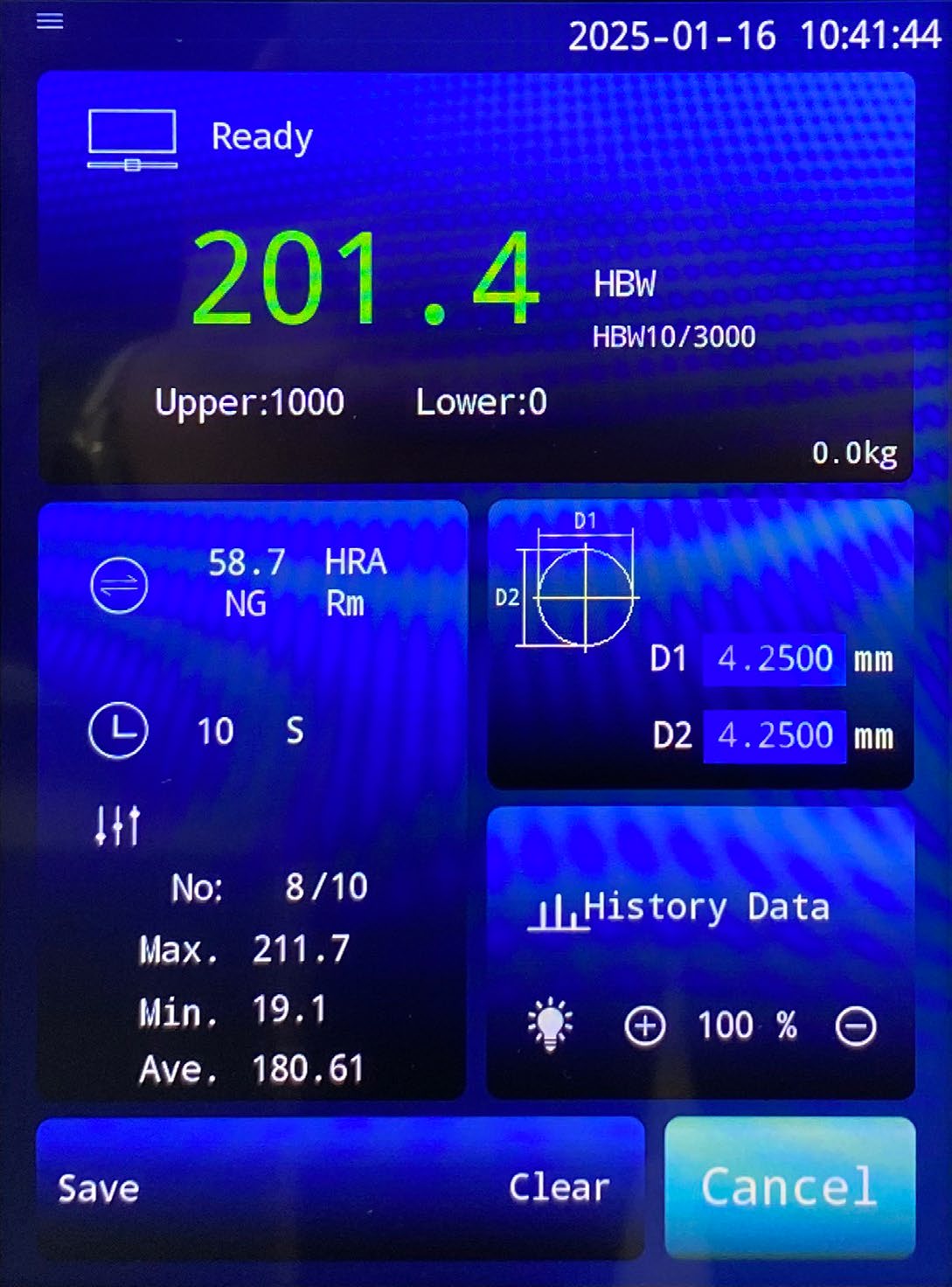

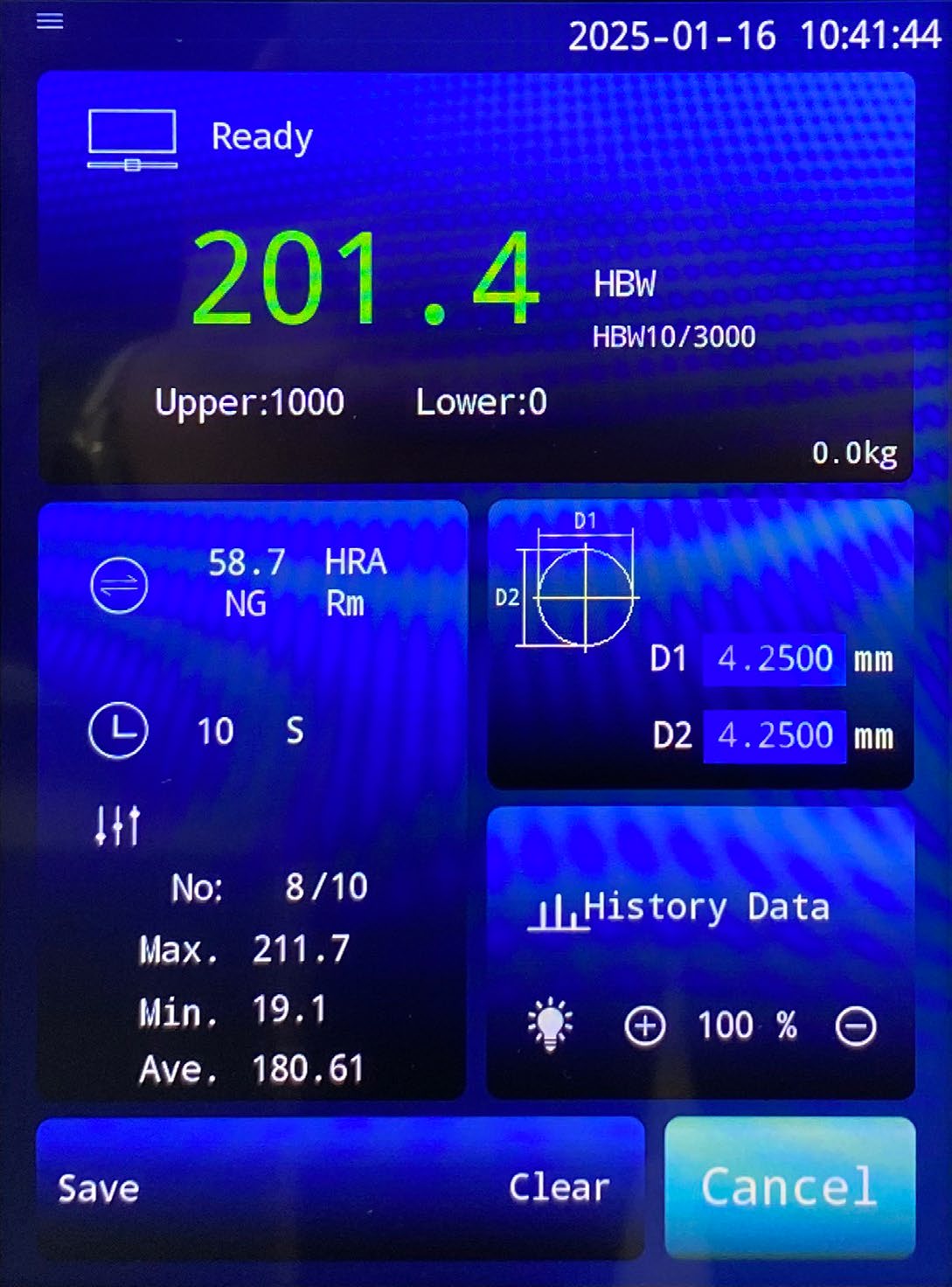

- User-Friendly Interface: Equipped with an 8-inch high-definition LCD touch screen, the instrument features an intuitive and simple operation interface. The interface displays key testing parameters (such as test force, holding time, and hardness value) clearly, and supports one-touch operation for common functions. Even operators with limited professional experience can quickly master its use, reducing training costs for enterprises.

- Precise Unit Conversion: The built-in accurate control system supports automatic conversion of units across the full hardness scale, including Brinell (HB), Rockwell (HRC, HRB), Vickers (HV), and Shore (HS) hardness units. This eliminates the need for manual calculation or external conversion tools, allowing users to directly obtain hardness values in their preferred unit according to testing standards or application requirements.

- Hardness Correction: Comes with a convenient software hardness value correction function. When minor deviations occur in test results due to long-term use or environmental changes, users can directly perform hardness value correction within a specified range through the touch screen interface, without the need for professional maintenance personnel or disassembly of the instrument, ensuring the long-term accuracy of the device.

- Efficient Data Management: Has a built-in large-capacity memory that can automatically group and save experimental data. Each data group can store up to 10 pieces of test data (including test time, hardness value, and test parameters), and the total database can hold over 1000 pieces of data. Users can easily query, export, or print historical data, facilitating traceability of test results and statistical analysis of product quality.

- Intelligent Alarm: Supports the setting of upper and lower limits for hardness values according to product quality standards. During testing, if the measured hardness value exceeds the preset range, the instrument will immediately trigger an automatic alarm (including sound and light prompts), prompting operators to timely check the material quality or testing process, effectively preventing unqualified products from flowing into the next process.

Application in Measuring Testing Instrument Field

As an essential Measuring Testing Instrument, this digital Brinell hardness tester plays a vital role in various industries. In the metallurgy industry, it is used to test the hardness of cast ingots, rolled plates, and forged parts to ensure material performance meets process requirements. In machinery manufacturing, it helps inspect the hardness of key components such as gears, shafts, and bearings, which is crucial for ensuring the service life and safety of mechanical equipment. In the electric power and petroleum machinery fields, it is applied to test the hardness of pipeline welds and pressure vessel materials to prevent safety hazards caused by insufficient hardness. Additionally, in the automotive industry, it is widely used for hardness testing of auto parts (like engine blocks and chassis components) to guarantee product quality and reliability.

Conclusion

The digital Brinell hardness tester stands out in the Measuring Testing Instrument market for its outstanding advantages such as full automation, high precision, user-friendliness, and intelligent data management. It not only simplifies the hardness testing process but also significantly improves the accuracy and efficiency of quality control. With Mikrosize's reliable supply chain, strict quality control, and professional after-sales service, this instrument remains a cornerstone tool for accurate hardness testing across industries, providing strong support for enterprises to improve product quality, reduce production costs, and enhance market competitiveness.