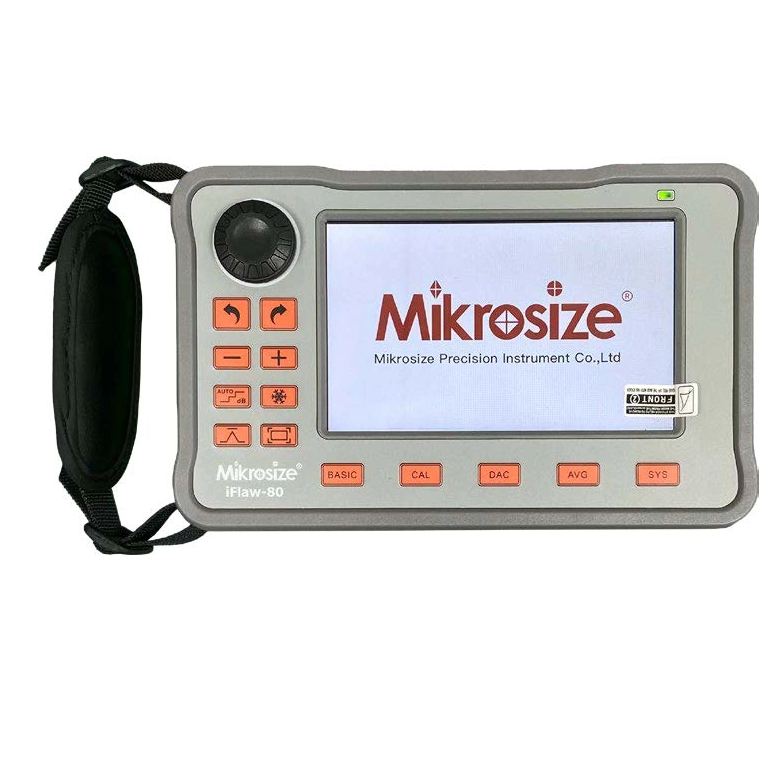

High-Quality Compact Ultrasonic Flaw Detector from Mikrosize: A Premium Measuring Testing Instrument

When it comes to reliable and high-performance non-destructive testing (NDT) solutions, the ultrasonic flaw detector supplied by Mikrosize stands out as a top-tier Measuring Testing Instrument. As a trusted supplier in the field of testing and measurement equipment, Mikrosize ensures that this compact ultrasonic flaw detector not only meets but exceeds industry standards, making it an indispensable tool for professionals across various sectors that demand precision in flaw detection.

This compact and superior-quality Measuring Testing Instrument from Mikrosize is engineered to deliver exceptional performance in every inspection scenario. At its core, the instrument features a spacious full VGA transparent display, which, when combined with Olympus' patented digital high dynamic range receiver, guarantees the display of stable and eye-catching A-scan images even in the most challenging lighting conditions—whether under bright sunlight in outdoor settings or dimly lit laboratory workspaces. This visual clarity is a key advantage for a Measuring Testing Instrument, as it directly impacts the accuracy of flaw identification, a critical factor in ensuring the safety and reliability of tested components.

Complying with the stringent requirements of the ISO-22232 standard, this ultrasonic flaw detector from Mikrosize (a leading Measuring Testing Instrument supplier) offers a comprehensive suite of standard and optional flaw detection functions. These functions are tailored to address a wide range of inspection needs, from routine checks to complex, specialized tests. What further enhances its value as a Measuring Testing Instrument is the integration of multiple onboard report production tools and a robust data archiving system. These features allow users to effortlessly collect, organize, and generate high-quality inspection reports—streamlining workflow processes and ensuring that critical data is easily accessible for analysis, documentation, and compliance purposes.

Durability and ergonomics are two pillars that define this Measuring Testing Instrument from Mikrosize. Built to withstand the rigors of diverse testing environments, the instrument boasts a sturdy construction that can endure harsh conditions, from the controlled settings of a laboratory workbench to the unpredictable and potentially dangerous outdoor sites, such as construction zones, oil rigs, or manufacturing plants. Its ergonomic design ensures that operators can use it comfortably for extended periods, reducing fatigue and enhancing productivity—an essential trait for a Measuring Testing Instrument that is often used in long inspection shifts.

The technical prowess of this ultrasonic flaw detector (a premium Measuring Testing Instrument by Mikrosize) is further amplified by its flexible PerfectSquare pulse generator and an extensive array of 30 digital filters. The PerfectSquare pulse generator allows for precise adjustments to suit different testing materials and thicknesses, while the 30 digital filters work tirelessly to enhance the signal-to-noise ratio. This combination ensures that even the smallest and most elusive flaws are detected with remarkable accuracy, solidifying the instrument's reputation as a reliable Measuring Testing Instrument for critical inspections. Additionally, with a 2 kHz pulse repetition frequency (PRF), the instrument enables fast scanning, making it highly efficient for high-volume inspection tasks—another key benefit for industries that require quick yet accurate results.

As a Measuring Testing Instrument that embodies the best of both performance and usability, this ultrasonic flaw detector from Mikrosize inherits the industry-leading detection performance of Olympus' conventional flaw detectors while adding the efficiency of intuitive operation and compact portability. The instrument’s interface is designed with user-friendliness in mind, featuring efficient menus and shortcut key access functions that put essential controls at the operator’s fingertips. This ensures that both seasoned ultrasonic testing professionals and novice users can master the instrument with ease, minimizing training time and maximizing operational efficiency—a crucial advantage for any Measuring Testing Instrument that needs to adapt to diverse user skill levels.

Mikrosize, as a dedicated supplier of high-quality Measuring Testing Instruments, understands that versatility is key for inspection tools. That’s why this ultrasonic flaw detector is designed to thrive in most testing environments. Its shuttle knob meets the IP66 rating standard, and the browsing key area complies with the IP67 rating—both of which indicate excellent protection against dust and water ingress. Moreover, the instrument has undergone rigorous testing in accordance with relevant environmental and reliability standards, ensuring that it maintains consistent operational performance and durability regardless of the conditions. Whether used in a clean laboratory, a dusty factory floor, or a rainy outdoor site, users can have full confidence in this Measuring Testing Instrument from Mikrosize.

Key Features of Mikrosize’s Ultrasonic Flaw Detector (A Premium Measuring Testing Instrument)

Compliance: Designed in strict accordance with the requirements of the ISO-22232 standard, ensuring adherence to global quality and safety benchmarks for Measuring Testing Instruments.

Pulse Generator: Equipped with a PerfectSquare Adjustable Square Pulse Generator, offering flexibility to adapt to various testing materials and scenarios.

Display Excellence: Features full screen A-scan mode and a large, full VGA display screen that is easily readable under sunlight—enhancing visibility for accurate flaw detection.

Receiver Technology: Incorporates a digital high dynamic range receiver (patented by Olympus) for stable and clear A-scan image display in all lighting conditions.

Signal Enhancement: Comes with 30 digital filters specifically designed to enhance the signal-to-noise ratio, ensuring precise detection of even minor flaws.

Fast Scanning: Boasts a 2 kHz pulse repetition frequency (PRF) that enables fast scanning, ideal for high-efficiency inspection tasks.

Intuitive Controls: Offers a flying shuttle knob or browsing key area for easy configuration adjustments, simplifying operation for all users.

Long Battery Life: Can operate for more than 15 hours using batteries, providing uninterrupted performance for all-day inspection projects—perfect for on-site testing where power sources may be limited.

Advanced Calibration: Includes standard dynamic DAC/TCG (Distance Amplitude Correction/Time Corrected Gain) and airborne DGS/AVG (Distance Gain Size/Average) functions, essential for accurate flaw sizing in a Measuring Testing Instrument.

Data Management: Supports multiple onboard report formats and uses a microSD memory card for convenient data transfer, facilitating efficient data storage and sharing.

Expansion Options: Offers an optional corrosion module software with encoded B-scan, expanding its capabilities for specialized corrosion inspection tasks.

Connectivity: Features a USB (OTG) port for seamless communication with PCs, alarm functions, VGA output, and optional analog output—enhancing its compatibility with other devices and systems.

User-Friendly Design: Ensures simple and comfortable operation, with an ergonomic layout that caters to both experienced and novice ultrasonic testing personnel.

The focus of Mikrosize’s ultrasonic flaw detector (a top-tier Measuring Testing Instrument) is to deliver high-level flaw detection performance through an easy-to-use, basic instrument. By combining advanced technology with intuitive design, Mikrosize has created a Measuring Testing Instrument that balances power and simplicity. Whether you are conducting routine maintenance checks, quality control inspections in manufacturing, or critical safety assessments in industries like aerospace, automotive, or oil and gas, this ultrasonic flaw detector from Mikrosize is the reliable partner you need. As a trusted supplier, Mikrosize is committed to providing Measuring Testing Instruments that empower professionals to make informed decisions, ensure product quality, and uphold safety standards—making this compact ultrasonic flaw detector a valuable addition to any inspection toolkit.