Mikrosize, a trusted provider of high-quality Measuring Testing Instruments, proudly presents its Coating Thickness Gauge—an economical, practical, and portable Measuring Testing Instrument designed to meet diverse thickness measurement needs across industries. This exceptional Measuring Testing Instrument stands out for its ability to quickly, non-destructively, and accurately measure the thickness of coatings and plating layers, making it an indispensable tool for both laboratory environments and on-site engineering applications. As a leading supplier in the field of Measuring Testing Instruments, Mikrosize ensures that this Coating Thickness Gauge combines affordability with top-tier performance, catering to the demands of professionals who rely on precise Measuring Testing Instruments for critical quality control tasks.

Product Overview: Mikrosize’s Advanced Measuring Testing Instrument

The Coating Thickness Gauge from Mikrosize is a cutting-edge Measuring Testing Instrument that employs two core thickness measurement methods—magnetic method and eddy current method—to achieve non-destructive, precise measurements. This versatility makes it a standout Measuring Testing Instrument, capable of handling two primary measurement scenarios:

Measuring the thickness of non-magnetic coatings (such as chromium, zinc, copper, aluminum, enamel, rubber, paint, and more) applied to magnetic metal substrates (including steel, iron, alloy, hard magnetic steel, etc.).

Measuring the thickness of non-conductive coatings (such as enamel, rubber, paint, plastic, and similar materials) on non-magnetic metal substrates (like copper, aluminum, zinc, tin, and others).

As a professional Measuring Testing Instrument, Mikrosize’s Coating Thickness Gauge leverages these methods to deliver consistent results, whether in controlled lab settings or harsh engineering sites. What sets this Measuring Testing Instrument apart is its compatibility with multiple probes, allowing users to customize measurements based on specific substrate and coating types—further solidifying its position as a flexible and reliable Measuring Testing Instrument from Mikrosize.

Magnetic Method (F-type Probe): A Key Feature of Mikrosize’s Measuring Testing Instrument

For the magnetic method, the Mikrosize Coating Thickness Gauge uses F-type probes (a critical component of this Measuring Testing Instrument) to operate on the principle of magnetic circuit variation. When the F-type probe of this Measuring Testing Instrument comes into contact with the coating layer, it forms a closed magnetic circuit with the underlying magnetic metal substrate. The presence of the non-magnetic coating disrupts the magnetic circuit, altering its magnetic resistance. This Measuring Testing Instrument then precisely measures this change in magnetic resistance and calculates the thickness of the coating layer—ensuring accuracy that users expect from a premium Measuring Testing Instrument by Mikrosize.

Eddy Current Method (N-type Probe): Another Core Function of Mikrosize’s Measuring Testing Instrument

The eddy current method, powered by N-type probes in Mikrosize’s Coating Thickness Gauge, is another highlight of this advanced Measuring Testing Instrument. This Measuring Testing Instrument generates a high-frequency alternating current within a coil, creating an electromagnetic field. When the N-type probe of the Measuring Testing Instrument touches the coating, eddy currents are induced on the surface of the non-magnetic metal substrate. These eddy currents produce a feedback effect on the coil inside the probe, and the Mikrosize Measuring Testing Instrument accurately measures the magnitude of this feedback to determine the coating’s thickness. This method underscores why Mikrosize’s Coating Thickness Gauge is a preferred Measuring Testing Instrument for non-conductive coating applications.

Functional Features: Why Mikrosize’s Coating Thickness Gauge Is a Top Measuring Testing Instrument

Mikrosize has engineered its Coating Thickness Gauge to be a feature-rich Measuring Testing Instrument, packed with capabilities that enhance usability, accuracy, and efficiency. As a leading Measuring Testing Instrument supplier, Mikrosize prioritizes user needs, and these features reflect that commitment:

Dual Measurement Methods: This Measuring Testing Instrument integrates both magnetic and eddy current methods, covering a wide range of coating-substrate combinations—making it a versatile Measuring Testing Instrument for diverse industries.

Multi-Probe Compatibility: The Mikrosize Coating Thickness Gauge, as a flexible Measuring Testing Instrument, supports up to 6 types of probes (F400, F1, F1/90°, F10, N1, CN02). Each probe is designed to optimize the Measuring Testing Instrument’s performance for specific coating and substrate types, ensuring precise results every time.

Dual Measurement Modes: Users can choose between Continuous measurement method and Single measurement method on this Measuring Testing Instrument. The continuous mode is ideal for rapid, sequential measurements (a boon for large-scale quality checks), while the single mode suits targeted, precise spot checks—proving this Measuring Testing Instrument adapts to different workflows.

Dual Working Modes: The Measuring Testing Instrument offers Direct mode (for immediate thickness readings) and Group mode (A-B) (for comparative measurements between two points), adding layers of functionality that make it a comprehensive Measuring Testing Instrument.

Comprehensive Statistical Analysis: As a data-driven Measuring Testing Instrument, it provides five key statistical measures: mean, maximum, minimum, number of tests, and standard deviation. This helps users derive actionable insights from measurement data—an essential feature for quality control teams relying on Measuring Testing Instruments for process improvement.

Flexible Calibration Options: To maintain the accuracy of this Measuring Testing Instrument, it supports single-point calibration and two-point calibration, along with basic calibration methods to correct systematic errors of the measuring head. This ensures the Mikrosize Coating Thickness Gauge remains a reliable Measuring Testing Instrument even after prolonged use.

Ample Data Storage: The Measuring Testing Instrument boasts a storage capacity of 495 measurement values, allowing users to store and retrieve data for later analysis or reporting—making it a convenient Measuring Testing Instrument for documentation-heavy industries.

Precise Data Deletion: This Measuring Testing Instrument lets users delete single suspicious data points (to eliminate outliers) or clear all stored data (for fresh measurement sessions), ensuring data integrity—a critical trait for any reliable Measuring Testing Instrument.

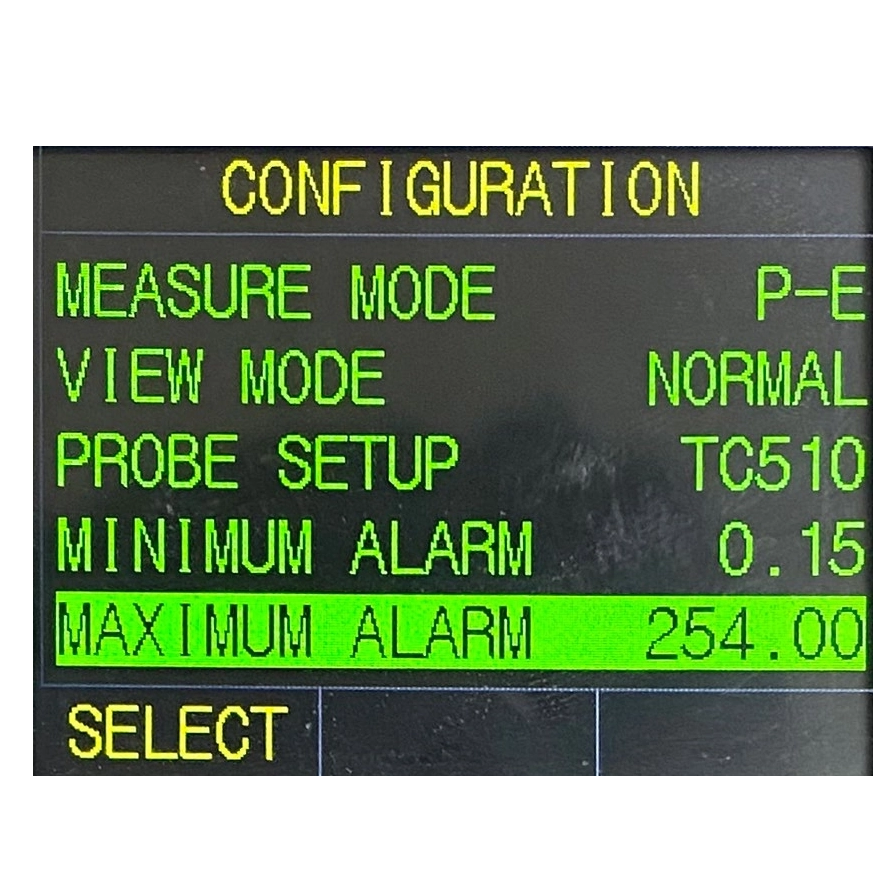

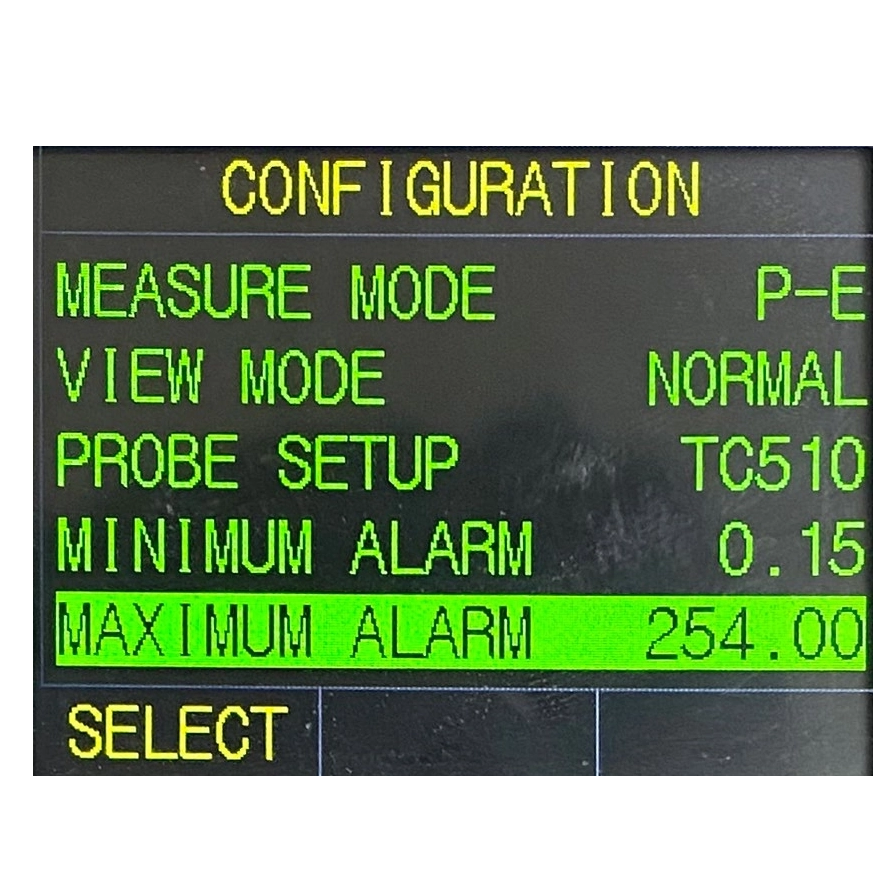

Adjustable Limit Alarms: Users can set custom measurement limits on this Measuring Testing Instrument; it triggers an automatic alarm when readings fall outside the set range, enabling real-time quality control—another reason why this is a trusted Measuring Testing Instrument.

Power Management Features: The Mikrosize Coating Thickness Gauge, as an efficient Measuring Testing Instrument, includes a power undervoltage indication function (alerting users when the battery is low) and two shutdown modes (manual and automatic). The automatic shutdown preserves battery life, making this Measuring Testing Instrument ideal for fieldwork where power access is limited.

User-Friendly Prompts: This Measuring Testing Instrument emits a buzzing sound during operation to confirm successful measurements, and it features an error prompt function (displayed on the screen and accompanied by beeps) to alert users to issues like probe misalignment or calibration errors—enhancing usability for all users of this Measuring Testing Instrument.

Wide Applications: Mikrosize’s Measuring Testing Instrument Across Industries

As a versatile Measuring Testing Instrument, Mikrosize’s Coating Thickness Gauge finds widespread use in numerous testing fields, thanks to its reliability and adaptability. Professionals across industries trust this Measuring Testing Instrument for quality assurance, process control, and compliance checks:

Manufacturing Industry: In automotive, electronics, and appliance manufacturing, this Measuring Testing Instrument is used to check coating thickness on parts (e.g., paint on car bodies, plating on electronic components) to ensure product durability and aesthetics.

Metal Processing Industry: For metal fabricators, this Measuring Testing Instrument verifies the thickness of protective coatings (like zinc plating on steel) that prevent corrosion—critical for maintaining product longevity.

Chemical Industry: In chemical plants, this Measuring Testing Instrument measures coatings on storage tanks, pipes, and equipment to ensure they resist chemical corrosion, safeguarding operational safety.

Commercial Inspection: Third-party inspection agencies rely on this Measuring Testing Instrument to verify coating thickness compliance with industry standards and client specifications, making it a trusted Measuring Testing Instrument for quality audits.

Why Choose Mikrosize’s Coating Thickness Gauge?

Mikrosize has built a reputation for delivering high-performance Measuring Testing Instruments, and the Coating Thickness Gauge is no exception. As a supplier dedicated to excellence in Measuring Testing Instruments, Mikrosize ensures this product combines affordability, portability, and precision—addressing the core needs of professionals who depend on Measuring Testing Instruments daily. Whether in a lab or on a construction site, the Mikrosize Coating Thickness Gauge stands as a reliable Measuring Testing Instrument that delivers consistent, accurate results, making it the top choice for anyone seeking a premium coating thickness Measuring Testing Instrument.