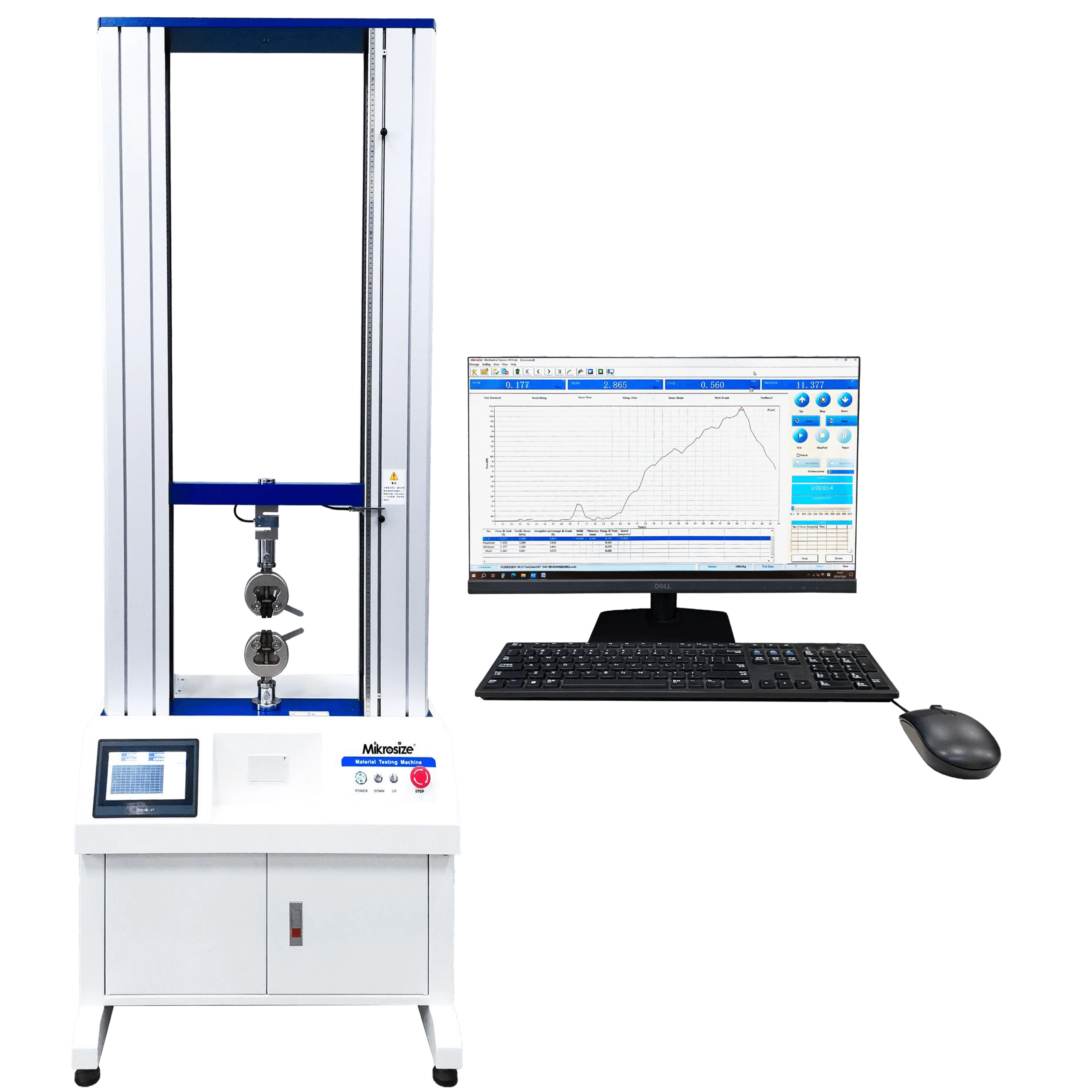

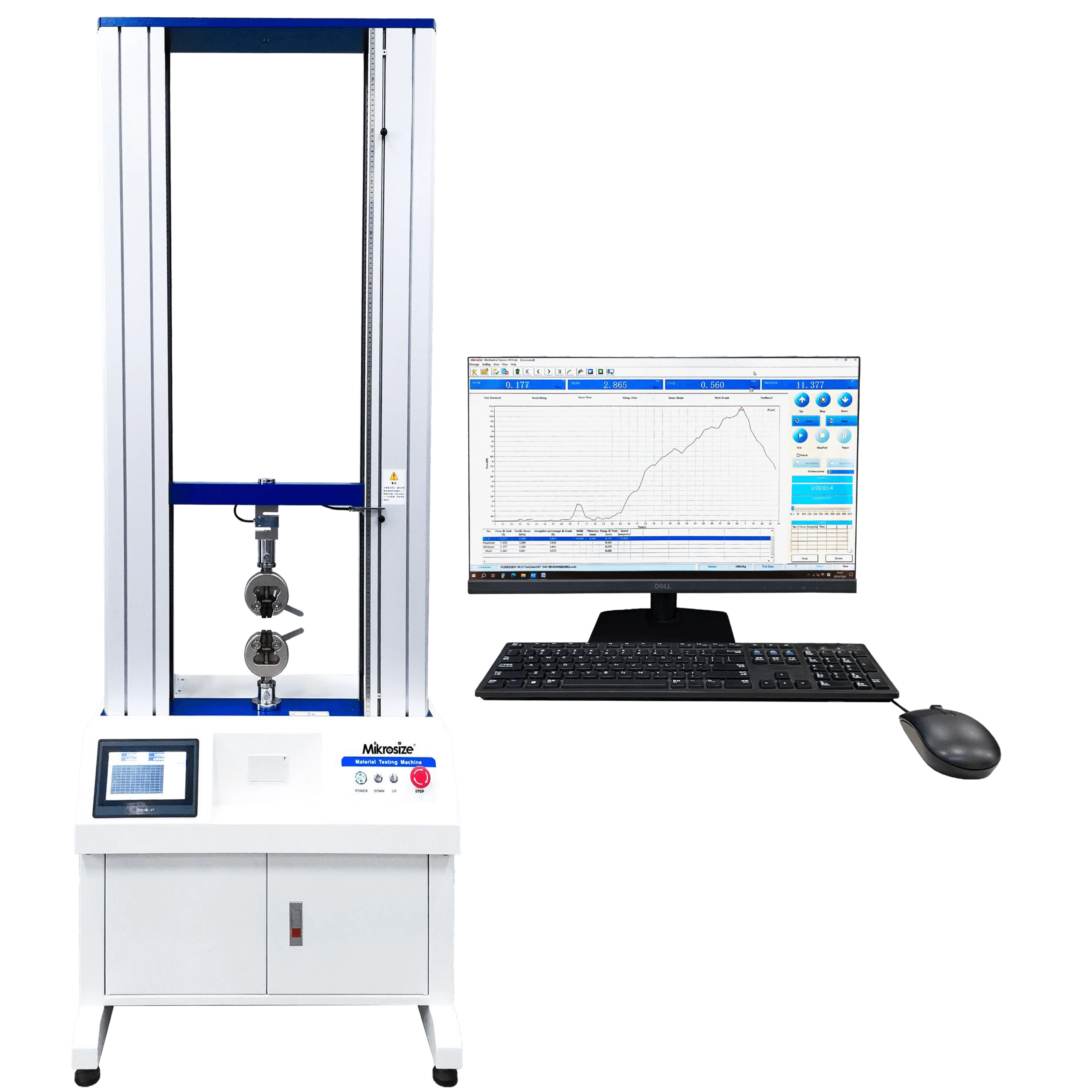

As a cutting-edge Measuring Testing Instrument designed for precision engineering, the Fully Automatic Insertion and Extraction Force Testing Machine, supplied by the renowned Mikrosize – a leading provider of high-quality testing equipment solutions – stands out as an indispensable tool in the field of connector performance evaluation. Mikrosize, with its expertise in developing and supplying top-tier measuring testing instruments, ensures that this automatic insertion and extraction force testing machine meets the most stringent industry standards, delivering reliable and accurate results for various manufacturing and quality control scenarios.

1. Functional Purpose

This Fully Automatic Insertion and Extraction Force Testing Machine, a flagship Measuring Testing Instrument from Mikrosize, is specifically engineered to conduct precise insertion and extraction force tests on a wide range of connector products and similar components. What sets this measuring testing instrument apart is its integration with a patented automatic centering device – a core technology that Mikrosize has optimized for maximum accuracy – enabling it to achieve completely precise insertion and extraction force test results, eliminating errors caused by misalignment.

Operated via a user-friendly Windows-based system with a Chinese interface, this Mikrosize-supplied measuring testing instrument offers exceptional ease of use, allowing even operators with basic technical knowledge to navigate its functions smoothly. In line with the high data management standards of premium measuring testing instruments, all test-related data can be securely stored, including test conditions, simulated displacement curve charts, life curve charts, detailed inspection reports, and more – ensuring comprehensive traceability for quality control and analysis.

Moreover, addressing a common pain point in connector testing, this Measuring Testing Instrument by Mikrosize effectively solves the fixture challenges associated with testing various types of connectors. During the testing process, male and female connectors can automatically align, completely avoiding the issue of one-sided feeding that often plagues conventional testing equipment. This not only enhances test accuracy but also significantly improves testing efficiency, making it a preferred choice for mass production lines and laboratory testing alike.

2. Technical Parameters

As a professional Measuring Testing Instrument, the Fully Automatic Insertion and Extraction Force Testing Machine by Mikrosize boasts impressive technical specifications that guarantee its performance and reliability:

Maximum Load: 50kg – capable of handling the testing needs of most standard and heavy-duty connectors, reflecting the robust design of this Mikrosize measuring testing instrument.

Minimum Resolution: 0.01gf – ensuring ultra-precise force measurement, a key advantage that positions this instrument as a high-end measuring testing solution.

Maximum Measuring Distance: 150mm – providing sufficient travel range to accommodate various connector sizes and insertion/extraction stroke requirements.

Fixture Size Range: 0~40mm – offering flexibility to fit different connector dimensions, a testament to the versatility of this Mikrosize measuring testing instrument.

Speed Range: 0-300mm/min – allowing users to simulate different real-world usage scenarios by adjusting the testing speed as needed.

X, Y-axis Movement Range: 0-75mm – facilitating precise positioning of the test specimens, further enhancing the accuracy of the measuring testing process.

Transmission Mechanism: Ball screw – ensuring smooth and stable movement of the testing components, which is crucial for consistent and reliable test results in a measuring testing instrument.

Exterior Dimensions: 360 * 260 * 940mm – compact in design, making it suitable for use in both laboratory settings and production floors with limited space.

Minimum Adjustment Distance: 0.01mm – enabling fine-tuning of the testing setup, a feature that underscores the precision of this Mikrosize measuring testing instrument.

Machine Weight: 76kg – providing a stable base during operation, preventing vibrations that could affect test accuracy.

Power Supply: 220V – compatible with standard power sources, ensuring easy integration into most industrial and laboratory environments.

3. Introduction to Testing Machine Software

The software of this Fully Automatic Insertion and Extraction Force Testing Machine – a critical component of the Measuring Testing Instrument by Mikrosize – is designed to enhance functionality, data management, and user experience, making it a comprehensive testing solution.

3.1 Main Testing Items

This Mikrosize measuring testing instrument’s software supports a wide array of testing items tailored to connector performance evaluation:

Analysis of connector plug-in life attenuation curves – helping users assess the durability and long-term performance of connectors.

Connector row insertion and extraction tests, as well as single PIN retention tests – covering key performance indicators of connector assemblies.

Tests for insertion force and displacement, and extraction force and displacement of connector products – the core functions of this measuring testing instrument, ensuring accurate measurement of force-displacement relationships.

Single hole plug and unplug tests for connectors, and Normal Force tests for connectors – addressing specific testing needs for different connector structures.

General compression and tensile failure tests – expanding the instrument’s application scope beyond connectors to other components requiring mechanical strength testing.

3.2 Main Functional Features

The software of this Mikrosize Measuring Testing Instrument is packed with user-centric features that elevate its practicality:

Ability to print and store graphics, including plug-in displacement curve charts, life curve charts, and inspection reports – enabling easy documentation and sharing of test results.

Beyond the original design, the software offers humanized machine surface testing functions, allowing users to conduct additional checks on the instrument’s status for optimal performance.

Test data is securely stored on the hard drive, with each piece of data capable of being stored an unlimited number of times – ensuring no loss of critical testing information, a key requirement for a reliable measuring testing instrument.

Testing conditions can be conveniently and quickly set via the computer screen, including parameters such as insertion and extraction stroke, speed, pause time, and more – saving time and reducing operational errors.

The header content of the inspection report can be modified at any time, supporting both Chinese and English – catering to the needs of global users and multinational enterprises.

Inspection reports can be easily transferred to and edited in WORD, EXCEL, and PDF files – facilitating seamless integration with existing quality management systems.

Equipped with a dynamic impedance testing system, this measuring testing instrument can simultaneously test the dynamic impedance of connectors while conducting insertion and extraction force tests, and generate a “load stroke impedance curve” – providing a more comprehensive understanding of connector performance under different conditions.

4. Instrument Protection Device

To ensure the safety of operators, the longevity of the equipment, and the accuracy of test results, this Measuring Testing Instrument by Mikrosize is equipped with a full set of reliable protection devices:

a. Instrument Overload Protection: When the applied force exceeds the maximum load capacity (50kg) of the measuring testing instrument, the system automatically shuts down the testing process, preventing damage to the instrument’s sensors and mechanical components.

b. Emergency Stop Device and Upper/Lower Travel Limit Device: The emergency stop device allows operators to immediately halt the instrument in case of an emergency, while the upper and lower travel limit devices prevent the testing components from moving beyond safe ranges, avoiding collisions and potential damage.

c. Software Setting Parameter Maximum Limit Protection: The software of this Mikrosize measuring testing instrument sets maximum limits for key testing parameters (such as speed and stroke). If users attempt to input values that exceed these safe limits, the system will issue a warning and reject the setting, ensuring the instrument operates within its optimal and safe performance range.

In conclusion, the Fully Automatic Insertion and Extraction Force Testing Machine, as a high-performance Measuring Testing Instrument supplied by Mikrosize, combines precision, functionality, and user-friendliness. Whether for laboratory research, product development, or mass production quality control, this instrument provides reliable and accurate testing solutions for connector manufacturers and related industries, solidifying Mikrosize’s reputation as a trusted supplier of top-tier measuring testing instruments.