As a leading provider of precision measurement solutions, Mikrosize specializes in developing and supplying high-performance Measuring Testing Instruments, and its portable surface roughness tester stands out as a flagship product—engineered to meet rigorous surface quality inspection demands across industries. This instrument integrates advanced sensing technology and user-centric design, making it an indispensable tool for quantifying surface roughness parameters (e.g., Ra) with exceptional accuracy and efficiency.

1. Application Areas: Where Mikrosize’s Measuring Testing Instrument Excels

Mikrosize’s portable surface roughness tester, as a versatile Measuring Testing Instrument, is widely adopted in sectors where surface finish directly impacts product performance, durability, and functionality. Its applications span three core domains:

1.1 Mechanical Processing & Manufacturing Industry

The instrument was originally tailored for metal processing—an area where surface roughness directly affects part fit, wear resistance, and lubrication. Mikrosize’s tester, particularly its stylus-type variant (a hallmark of its Measuring Testing Instrument lineup), is optimized for hard metal surfaces (e.g., steel, aluminum alloys) common in key fields. In automotive manufacturing, it inspects engine components (crankshafts, camshafts), transmission parts (gears, bearings), and chassis hardware—ensuring smooth operation and extended service life. For general mechanical engineering, it tests precision machined parts (valves, shafts, fittings) to verify compliance with industry standards (e.g., ISO 4287) and customer specifications. In these fields, Mikrosize’s Measuring Testing Instrument is not just a quality control tool but a critical enabler of consistent, high-performance production.

1.2 Non-Metallic Processing Industry

With the rise of advanced materials, Mikrosize has upgraded its Measuring Testing Instrument to accommodate non-metallic workpieces—addressing the need for surface quality control in materials that substitute metals for weight, corrosion resistance, or cost benefits. For ceramics, it tests the surface of ceramic bearings (used in high-speed machinery) and dental ceramics, where roughness influences biocompatibility and friction. In polymers and plastics, it inspects polyethylene (PE) pumps/valves (for chemical processing), polycarbonate (PC) optical components, and 3D-printed plastic parts—ensuring functionality (e.g., leak-proof seals) and aesthetic quality. For composites, it evaluates carbon fiber-reinforced polymer (CFRP) surfaces for aerospace or automotive parts, where roughness affects bonding strength with adhesives or coatings. Mikrosize’s tester adapts seamlessly to these materials, leveraging its adjustable stylus pressure and sensitive sensors to avoid surface damage while delivering reliable data.

1.3 Emerging & Daily-Use Sectors

As Mikrosize refines the technology and functionality of its Measuring Testing Instrument, its utility has expanded beyond traditional manufacturing to industries and scenarios where surface roughness was once overlooked. In the electronics and communication sector, it tests the surface of semiconductor wafers, printed circuit board (PCB) contacts, and switch couplings—ensuring stable electrical conductivity and minimal signal interference. For the power industry, it inspects turbine blades (metallic or composite) and transformer components, where roughness impacts airflow efficiency and heat dissipation. Even in daily life and healthcare, it evaluates the surface of tableware (for food safety and comfort), stationery (e.g., pen nibs for smooth writing), and human teeth (for dental treatments like veneers or orthodontics). In each case, Mikrosize’s Measuring Testing Instrument brings laboratory-grade precision to on-site or production-line inspections, bridging the gap between quality and practicality.

2. Working Principle: The Science Behind Mikrosize’s Measuring Testing Instrument

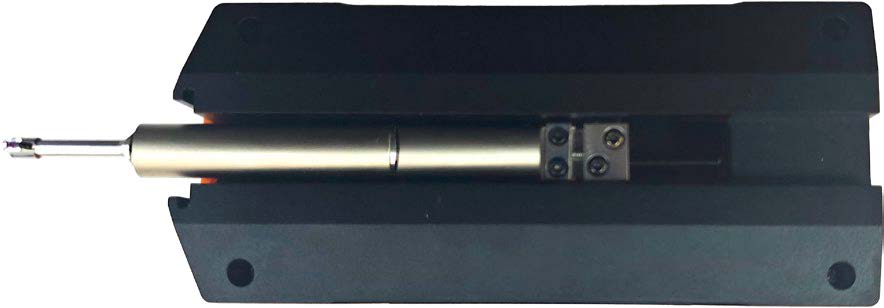

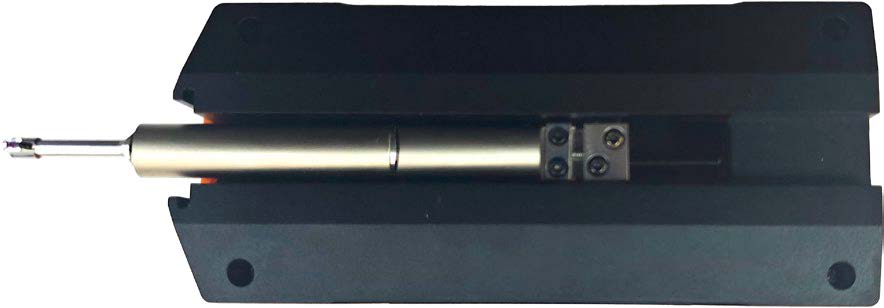

Mikrosize’s portable surface roughness tester operates on the needle drawing (touch needle) method—a proven technique that balances accuracy and ease of use, and the core of its Measuring Testing Instrument technology. Below is a detailed breakdown of its components and operational process:

2.1 Core Components

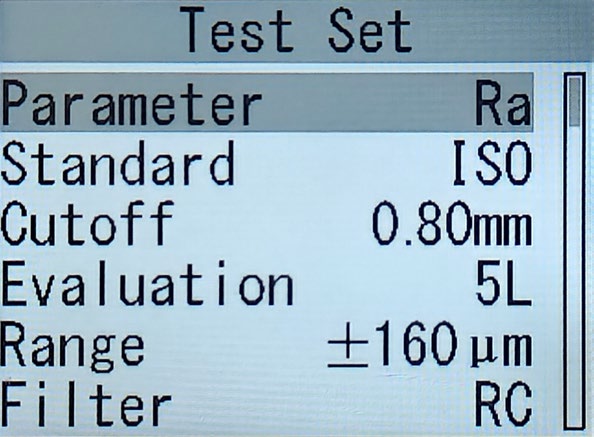

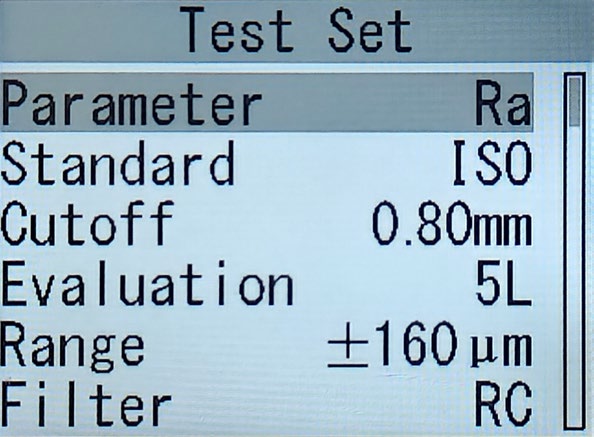

The instrument comprises five key modules, each optimized by Mikrosize for reliability and performance. The inductive sensor, the heart of the system, features a diamond-tipped stylus (with a curvature radius of 2μm–10μm, depending on the model) mounted on a flexible measuring rod; the stylus’s hardness (diamond) ensures minimal wear, while its small tip captures fine surface undulations. The driver mechanism is a precision motor that drags the sensor across the workpiece at a constant speed (typically 0.1mm/s–1mm/s, adjustable via Mikrosize’s user interface), ensuring consistent data collection. The signal processing unit is equipped with a high-speed DSP (Digital Signal Processor) chip—exclusive to Mikrosize’s Measuring Testing Instrument—that processes raw sensor data in real time. The display & output module includes a segment-code LCD with backlight (for low-light environments) and connectivity options (RS232, USB) for data export. Finally, the calibration & zeroing system features a built-in zero point gauge and standard reference block (supplied with every Mikrosize tester) to ensure accuracy before each use.

2.2 Step-by-Step Operation

Before testing, pre-measurement calibration is essential: the user adjusts the zero point gauge to center the sensor’s magnetic core within two differential inductance coils. This ensures the instrument operates within its linear inductance range—critical for precise readings, a step Mikrosize emphasizes in its Measuring Testing Instrument user guides. Next, the sensor is placed vertically on the workpiece surface; the driver mechanism moves the sensor smoothly along the measurement path, and as the stylus encounters surface undulations (peaks and valleys), it moves up and down. This vertical motion syncs with the magnetic core’s movement inside the inductance coils, altering the coils’ inductance. Since the coils are part of a balanced Wheatstone bridge, this inductance change disrupts the bridge’s equilibrium, generating an analog electrical signal proportional to the stylus’s displacement.

The analog signal is then sent to the DSP chip (a key upgrade in Mikrosize’s latest Measuring Testing Instrument). The chip first applies noise filtering (to eliminate environmental interference) and waviness filtering (to isolate roughness from larger surface variations, per ISO standards), then amplifies the purified signal and converts it to a digital format. Finally, the DSP calculates the Ra value (arithmetic mean deviation of the assessed profile)—the most widely used roughness parameter—by integrating the absolute values of the stylus’s vertical displacements. Results are displayed on the LCD (in μm or μin) and can be stored in the instrument’s internal memory (for up to 1,000 readings), printed via Mikrosize’s compatible TA220s printer, or exported to a PC for further analysis (e.g., SPC—Statistical Process Control). Mikrosize’s Measuring Testing Instrument is calibrated to measure Ra values ranging from 0.02μm to 10μm; specialized models (e.g., those with small-hole sensors) can detect values as low as 0.005μm, catering to ultra-precision applications.

3. Main Features: What Sets Mikrosize’s Measuring Testing Instrument Apart

Mikrosize’s portable surface roughness tester is designed to combine laboratory accuracy with field practicality—reflecting the brand’s commitment to user-centric Measuring Testing Instrument innovation. Its key features include:

High-Precision Inductive Sensor: Equipped with a diamond stylus that offers exceptional wear resistance, paired with low-noise inductive coils. This combination ensures a repeatability of ±2% and a resolution of 0.001μm, critical for consistent quality control across batches.

User-Friendly Interface: Features a segment-code LCD with backlight, ensuring readability in both bright production floors and dimly lit workshops. The human-computer dialogue design is intuitive, with clearly labeled touch buttons—even non-experts can master basic operation in 10 minutes.

DSP-Powered Performance: Integrates a custom Mikrosize DSP chip that enables fast data processing (completing a full measurement cycle in <3 seconds) while maintaining low power consumption, extending overall battery life for all-day use.

Long-Lasting Battery: Built with a 3.7V lithium-ion rechargeable battery (5,000mAh) that has no memory effect—eliminating the need for full discharge before charging. It charges fully in just 2 hours and supports over 20 hours of continuous use, making it ideal for shift-based production lines.

Mechatronic Design: Boasts a compact form factor (150mm × 80mm × 50mm) and lightweight build (350g, including the battery). This portability allows easy transport to on-site locations, such as large machinery installations or outdoor workshops, without sacrificing performance.

Versatile Data Management: Can store up to 1,000 readings, with a data query function that lets users retrieve results by date and time. Its built-in RS232 interface supports seamless integration with printers, PCs, or factory IoT systems, streamlining data logging and quality reporting.

Smart Functions: Includes an automatic shutdown feature that activates after 5 minutes of inactivity, saving power when not in use. It also has LED prompts for low battery, calibration reminders, and measurement completion—reducing human error and ensuring consistent operation.

Customizable Accessories: Offers a range of optional add-ons exclusive to Mikrosize’s Measuring Testing Instrument, such as a small-hole sensor (for holes with a diameter of ≥2mm), a deep-groove sensor (for grooves with a width of ≥1mm), a magnetic measurement platform (for securing ferrous workpieces), and an extension rod (for accessing hard-to-reach surfaces like engine blocks).

4. Instructions for Use: Maximizing Mikrosize’s Measuring Testing Instrument

To ensure accurate and efficient operation, Mikrosize provides detailed guidelines for its Measuring Testing Instrument. Below is a structured overview of measurement methods and step-by-step procedures:

4.1 Common Measurement Methods

Mikrosize’s tester supports four industry-standard methods, with the needle drawing method as its primary and most widely used function.

The needle drawing method—the core technology of Mikrosize’s tester—involves a stylus scanning the surface; the stylus’s displacement is converted into an Ra value. It is ideal for quantitative, precise measurements (covering Ra values of 0.02μm–10μm) across metals, ceramics, plastics, and other hard materials.

The interference method uses light wave interference (either laser or white light) to visualize surface undulations. This non-contact approach is perfect for ultra-sensitive surfaces that could be damaged by a stylus, such as polished optics or thin films.

The comparative method involves comparing the test surface to Mikrosize’s standard roughness samples (which have pre-calibrated Ra values). Evaluation is done via visual inspection (using a magnifier) or tactile feedback (running a nail or finger across the surface). This method is quick and qualitative, best suited for workshop checks where Ra values are greater than 1μm—no power or complex setup is required.

The light cutting method uses a microscope to project a “light slice” onto the surface, then measures undulation height via optical imaging. It is designed for high-magnification inspection of small, precision parts like watch components or micro-electromechanical systems (MEMS).

4.2 Step-by-Step Operation (Needle Drawing Method)

Prepare the Workpiece: First, clean the test surface to remove oil, dust, or debris—contaminants can skew readings. Mikrosize recommends using lint-free wipes and isopropyl alcohol for cleaning metal and plastic surfaces; for delicate ceramics, use a soft brush to avoid scratches.

Calibrate the Instrument: Place the sensor on Mikrosize’s standard reference block (supplied with every tester). Press the “Calibrate” button; the instrument will automatically adjust the zero point gauge to center the magnetic core in the inductance coils. Once calibration is successful, the LCD will display “CAL OK”—do not proceed with measurement if calibration fails (contact Mikrosize support if issues persist).

Mount the Sensor: Select the appropriate sensor (standard, small-hole, or deep-groove) based on the workpiece’s shape and size, then attach it firmly to the instrument. For curved surfaces (e.g., cylindrical shafts or spherical parts), use Mikrosize’s magnetic measurement platform to secure the workpiece—this ensures the stylus maintains vertical contact with the surface during scanning.

Start Measurement: Position the stylus lightly on the test surface—avoid applying excessive pressure, as this can damage both the stylus and the workpiece. Press the “Measure” button; the driver mechanism will move the sensor at the preset speed (default: 0.5mm/s, adjustable via the settings menu). The LCD will show real-time measurement progress; once complete, the Ra value (and other optional parameters like Rz, if enabled) will be displayed prominently.

Save/Export Data: Press the “Store” button to save the reading to the instrument’s memory (label readings with a timestamp for easy retrieval later). To export data, use the “Print” function to connect to Mikrosize’s TA220s printer, or use the “PC Link” function to transfer data to a computer for further analysis (e.g., generating quality control reports).

Post-Measurement Care: After use, wipe the stylus with the soft brush supplied by Mikrosize to remove any residue. Turn off the instrument manually or let it enter standby mode (it will shut down automatically after 5 minutes of inactivity). Store the tester and accessories in the provided case to protect against dust and impact.

5. Why Choose Mikrosize’s Measuring Testing Instrument?

Mikrosize’s portable surface roughness tester is more than a tool—it’s a solution engineered to solve real-world inspection challenges. As a trusted provider of Measuring Testing Instruments, Mikrosize offers three key advantages that set it apart from competitors.

First, reliability: Each tester undergoes rigorous quality control checks in compliance with ISO 9001 standards. It is built to withstand harsh industrial environments, with a rugged outer casing that resists dust and minor impacts, ensuring consistent performance even in busy production facilities.

Second, comprehensive support: Mikrosize provides detailed user manuals, video tutorials, and 24/7 global after-sales service. Whether you need help with calibration, sensor replacement, or troubleshooting, their team of experts is available to assist—minimizing downtime for your operations.

Third, flexibility: The tester’s customizable configurations (including a range of sensors and accessories) allow it to adapt to unique application needs. From automotive factories testing large engine parts to dental labs evaluating ceramic crowns, Mikrosize’s Measuring Testing Instrument can be tailored to fit your workflow.

For businesses and professionals seeking a balance of precision, portability, and ease of use, Mikrosize’s Measuring Testing Instrument is the definitive choice for surface roughness inspection—delivering accurate data, reliable performance, and unmatched value.