When it comes to selecting the appropriate rock hardness gauge for your specific needs, a solid understanding of its core principles, classifications, and performance metrics is essential. Among the leading providers of high-quality Measuring Testing Instruments in this field is Mikrosize, a trusted supplier renowned for offering a wide range of reliable and precise rock hardness gauges that cater to diverse industrial and laboratory applications. Whether you are in the mining, construction, material science, or manufacturing sector, Mikrosize’s Measuring Testing Instruments are designed to meet the rigorous demands of rock hardness testing, ensuring accuracy and consistency in every measurement.

First, let’s delve into the principle of rock hardness testing, specifically focusing on the Rockwell hardness principle—one of the most widely used methods in the industry. The Rockwell hardness principle is based on the depth of indentation: when a indenter (of specific shape and material) is pressed into the surface of a rock sample under a predetermined load (force value), the hardness of the rock is determined by measuring the depth of the indentation left by the indenter. Different indenters are paired with different force values to accommodate the varying hardness levels of different rock types; once the indentation is made, the hardness value can be directly read from the gauge. This principle is straightforward yet highly effective, making it a cornerstone of rock hardness testing. For those seeking in-depth technical details, relevant literature and technical manuals (often provided alongside Mikrosize’s Measuring Testing Instruments) offer comprehensive explanations to support precise testing operations.

Next, understanding the classification of rock hardness gauges is crucial for selecting the right tool, as different classifications are tailored to specific testing scenarios and requirements. Mikrosize, as a leading supplier of Measuring Testing Instruments, offers a full range of rock hardness gauges covering all key classifications, ensuring that customers can find the perfect match for their needs.

Classification by Scale

Classification by Scale

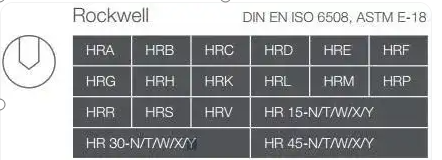

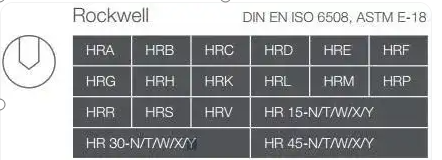

Ordinary Rock Hardness Meter: This type of gauge is designed to test hardness values on the HRA, HRB, HRC, and other common Rockwell scales—totaling 15 standard scales. It is ideal for testing rocks with moderate to high hardness and is widely used in general industrial settings. Mikrosize’s ordinary rock hardness meters are engineered with user-friendly features, making them suitable for both experienced technicians and those new to hardness testing.

Surface Rock Hardness Meter: Specifically designed for testing the surface hardness of rocks (where the surface layer may have different properties from the core), this gauge uses scales such as HR15N, HR30N, HR45N, HR15T, and others, also covering 15 standard scales. It is particularly useful in applications where surface integrity is critical, such as in the assessment of rock samples used in construction or heritage preservation. Mikrosize’s surface rock hardness meters are equipped with precise indentation control to ensure accurate measurement of surface hardness without damaging the sample.

Plastic Rock Hardness Meter: This gauge is tailored for testing rocks with relatively low hardness or plastic-like properties, using plastic-specific Rockwell scales including HRE, HRL, HRM, HRR, and more. It is commonly used in testing soft rock formations or rock samples that exhibit slight deformability. Mikrosize’s plastic rock hardness meters are designed with sensitive load sensors to capture even minor indentation depths, ensuring reliable readings for soft materials.

All-Range Rock Hardness Meter: As the most versatile option, this gauge can test hardness values across all Rockwell scales, including those for ordinary, surface, and plastic applications (covering Plo, Taylor, and plastic scales)—totaling 30 Rockwell scales. It is the ideal choice for laboratories, research institutions, or facilities that need to test a wide variety of rock types with varying hardness levels. Mikrosize’s all-range rock hardness meters are equipped with advanced technology, allowing for seamless switching between scales and automatic calibration, making them a top choice for high-volume, multi-purpose testing.

Classification by Machine Type

Desktop Rock Hardness Meter: Designed for stationary use in laboratories or workshops, this type of gauge offers high stability and precision, making it suitable for detailed, controlled testing. It is often used in quality control labs where consistent testing conditions are required. Mikrosize’s desktop rock hardness meters feature robust construction and integrated data logging capabilities (a key feature of their Measuring Testing Instruments), allowing for easy storage and analysis of test results.

Portable Rock Hardness Meter: Built for on-site testing, this lightweight and compact gauge is perfect for fieldwork—such as testing rock formations at construction sites, mines, or remote geological locations. It eliminates the need to transport large rock samples back to the lab, saving time and resources. Mikrosize’s portable rock hardness meters are designed with durable, weather-resistant materials to withstand harsh field conditions, while still maintaining the high accuracy that their Measuring Testing Instruments are known for.

Classification by Display Type

Pointer-Type (Dial Reading) Rock Hardness Meter: This traditional type of gauge uses a dial to display hardness values, with manual loading and unloading of the indenter. It is simple to operate and cost-effective, making it a popular choice for basic testing needs. Mikrosize’s pointer-type gauges are crafted with high-precision dials that are easy to read, ensuring reliable results even in low-light conditions.

Digital Display (LCD or Touch Screen) Rock Hardness Meter: A more advanced option, this gauge features an LCD or touch screen display, with automatic loading and unloading of the indenter—eliminating human error in the testing process. Hardness values are automatically calculated and displayed, and many models also offer data export capabilities for further analysis. Mikrosize’s digital display rock hardness meters are part of their premium line of Measuring Testing Instruments, incorporating cutting-edge technology to deliver fast, accurate, and user-friendly testing experiences.

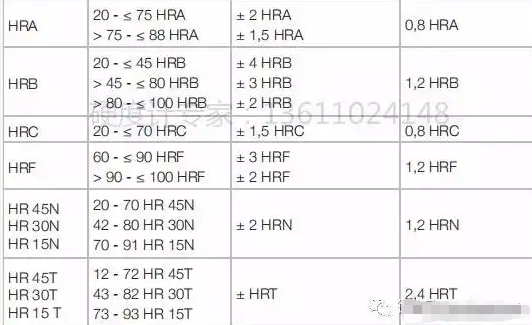

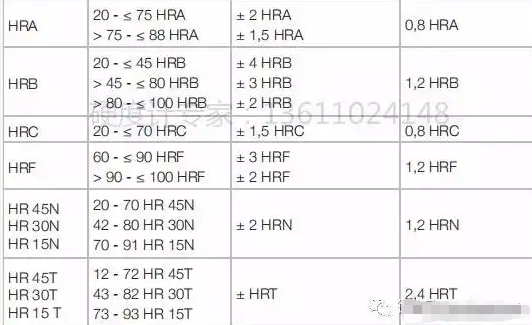

In addition to understanding the principle and classification of rock hardness gauges, it is equally important to consider the error range of the testing equipment— as this directly impacts the reliability of the test results. For Rockwell hardness testing, the error range is defined by two key metrics: acceptable reproducibility accuracy and limit deviations (measured in Rockwell hardness units, HB) across different rock hardness ranges. Mikrosize’s Measuring Testing Instruments are rigorously calibrated to meet or exceed industry standards for error range, ensuring that every test result is consistent and trustworthy. The company provides detailed specifications for each rock hardness gauge, outlining the acceptable reproducibility accuracy and limit deviations for different hardness ranges—allowing customers to select a gauge that meets their specific precision requirements.

In summary, choosing the right rock hardness gauge requires a clear understanding of the Rockwell hardness principle, the various classifications of gauges (by scale, machine type, and display type), and the error range of the equipment. With Mikrosize as your trusted supplier of Measuring Testing Instruments, you can rest assured that you will have access to a comprehensive range of high-quality rock hardness gauges—each designed to deliver accurate, reliable, and efficient testing results. Whether you need a desktop gauge for laboratory use, a portable gauge for fieldwork, a digital display gauge for advanced data analysis, or an all-range gauge for versatile testing, Mikrosize’s Measuring Testing Instruments are tailored to meet your unique needs. By leveraging Mikrosize’s expertise and high-performance equipment, you can streamline your rock hardness testing process and make informed decisions based on precise, trustworthy data.

Classification by Scale

Classification by Scale