In modern manufacturing and scientific research, high-precision measurement and inspection are the core links to ensure product quality and promote technological innovation. A detection device that combines accuracy, multi-functionality and stability can often become a "powerful assistant" for various industries to improve efficiency and control quality. The VMC-3020P CNC vision measuring system is precisely such a photoelectric detection device integrating precision machinery and advanced technology. Centered on two-dimensional measurement, it also supports three-dimensional measurement. With excellent hardware configuration, outstanding performance and powerful software functions, it is widely used in electronics, machinery, molds, automobiles and other fields, providing efficient and reliable solutions for measurement and inspection work.

The robust configuration lays a solid foundation for precise measurement. The outstanding performance of the VMC-3020P CNC video measuring system primarily stems from its "hardcore" hardware configuration. The mainframe is equipped with a series of high-quality components, among which the combination of surface light source and Renishaw probes of renowned brands provides a solid guarantee for precise detection and data acquisition. The worktable is made of "00" grade black granite, which features excellent stability and anti-deformation ability, effectively avoiding the interference of external environmental factors on measurement accuracy. Its size reaches 360*260mm and the load capacity is up to 25kg. Whether it is small precision parts or larger-sized objects to be measured, it can be easily adapted, greatly expanding the application range of the equipment.

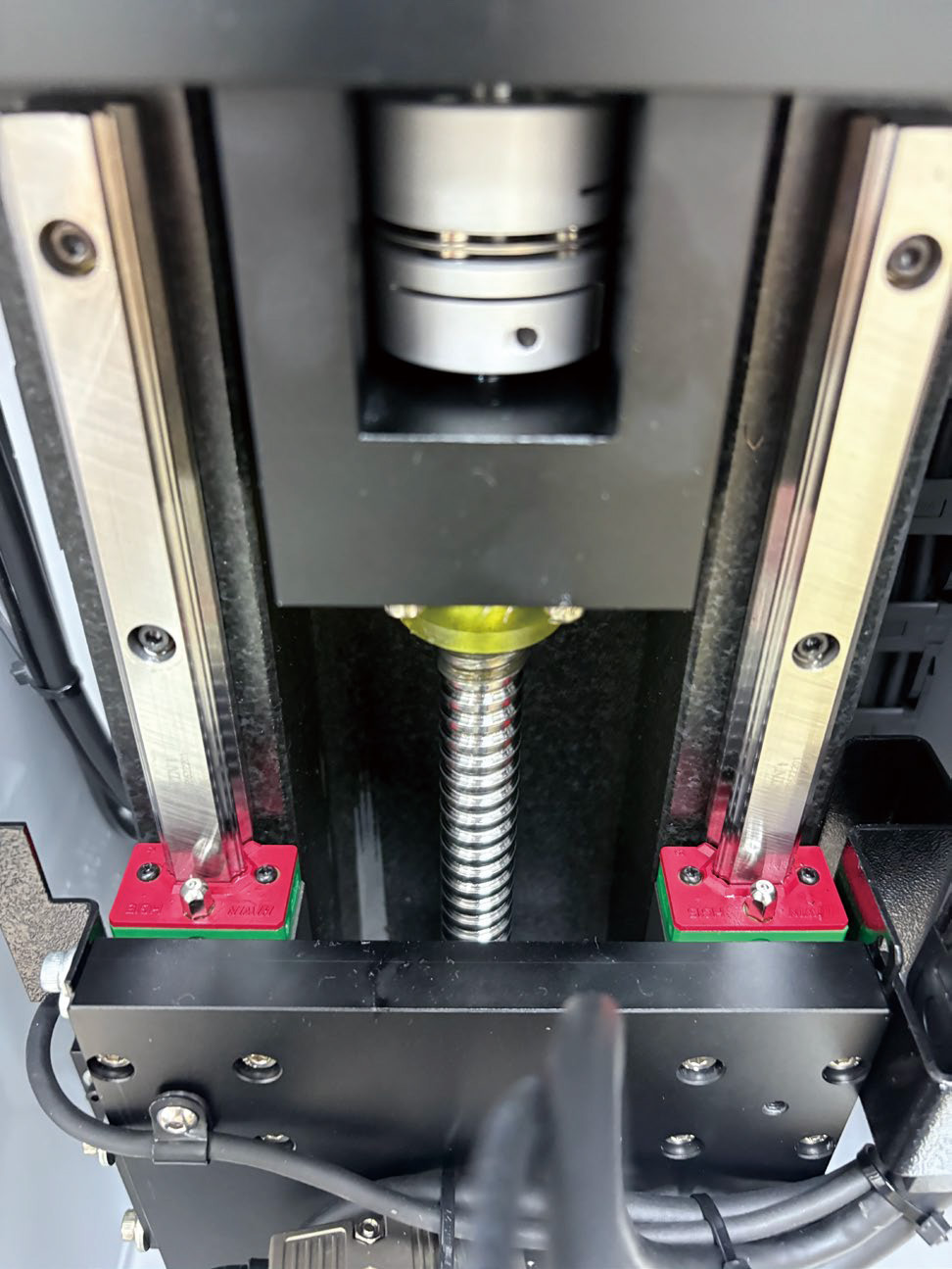

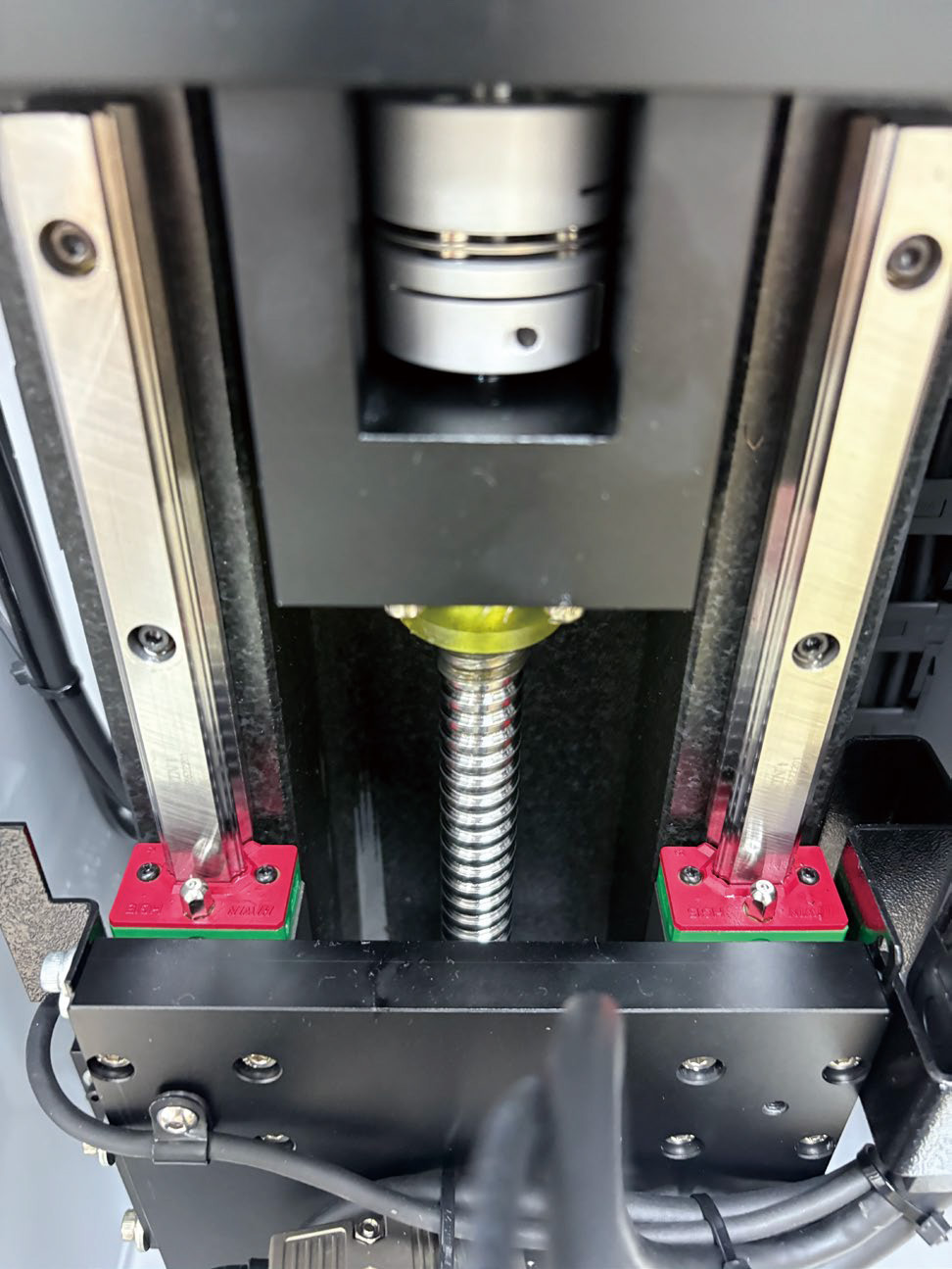

In terms of the transmission system, the equipment adopts precision linear guides and ground-level ball screws, combined with advanced CNC servo control technology, achieving a resolution of 0.5μm for the X/Y/Z axes and a repeatability as precise as ±2μm. This means that during repeated measurements, the equipment can still maintain extremely high consistency and accuracy, laying a solid foundation for various high-precision measurement tasks. Even for the detection of minute dimensions, it can achieve "pinpoint accuracy".

Outstanding performance, unlocking an efficient inspection experience

If hardware configuration is the "skeleton" of a device, then performance is its "soul". The VMC-3020P CNC vision measuring system stands out particularly in terms of performance, fully meeting the high-precision inspection requirements in various scenarios.

Renishaw probes, as the "perceptive weapon" of the equipment, not only have extremely high precision but also a repeatability of 0.75μm. They are highly sensitive and can quickly and accurately capture the minute features of the measured object, whether it is a complex geometric contour or a tiny dimensional deviation. The imaging system adopts imported optical components and a color CCD, combined with a 0.7-4.5X automatic zoom lens, achieving a magnification effect of 23.5-148X. This configuration enables the equipment to clearly present the microscopic structure of the measured object. Even details that are difficult to discern with the naked eye can be clearly visible in the image, providing a clear visual basis for subsequent precise measurements.

In addition, the lighting system of the equipment is also worthy of praise. The 5-ring 8-zone surface light with 256-level adjustment and the parallel contour light can flexibly adjust the light intensity and angle according to the material, shape of the object to be measured and the detection requirements, ensuring that the imaging is always clear and uniform, effectively avoiding measurement errors caused by light issues, and further improving the accuracy and reliability of the detection.

Intelligent software, empowering full-process inspection management

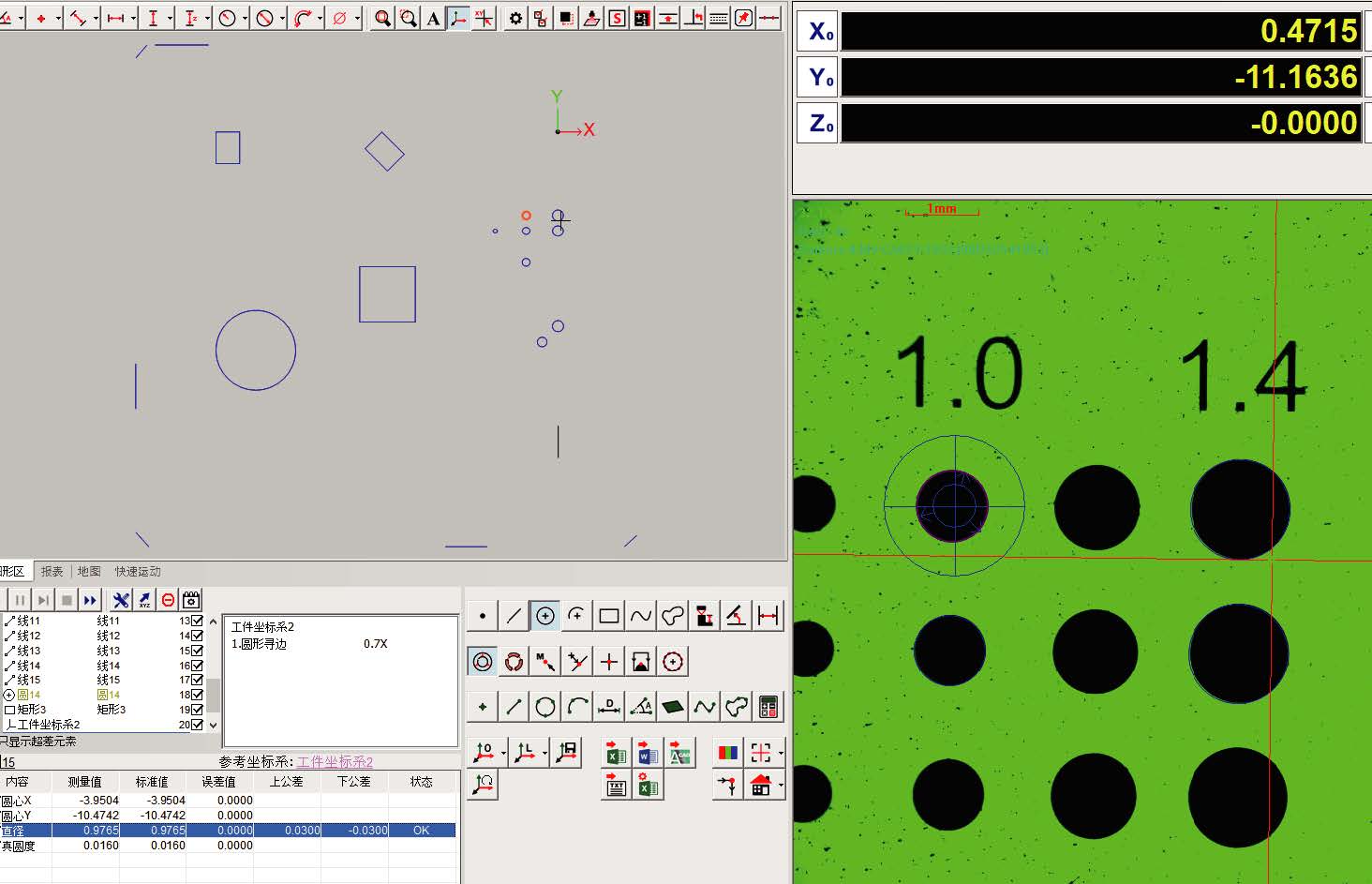

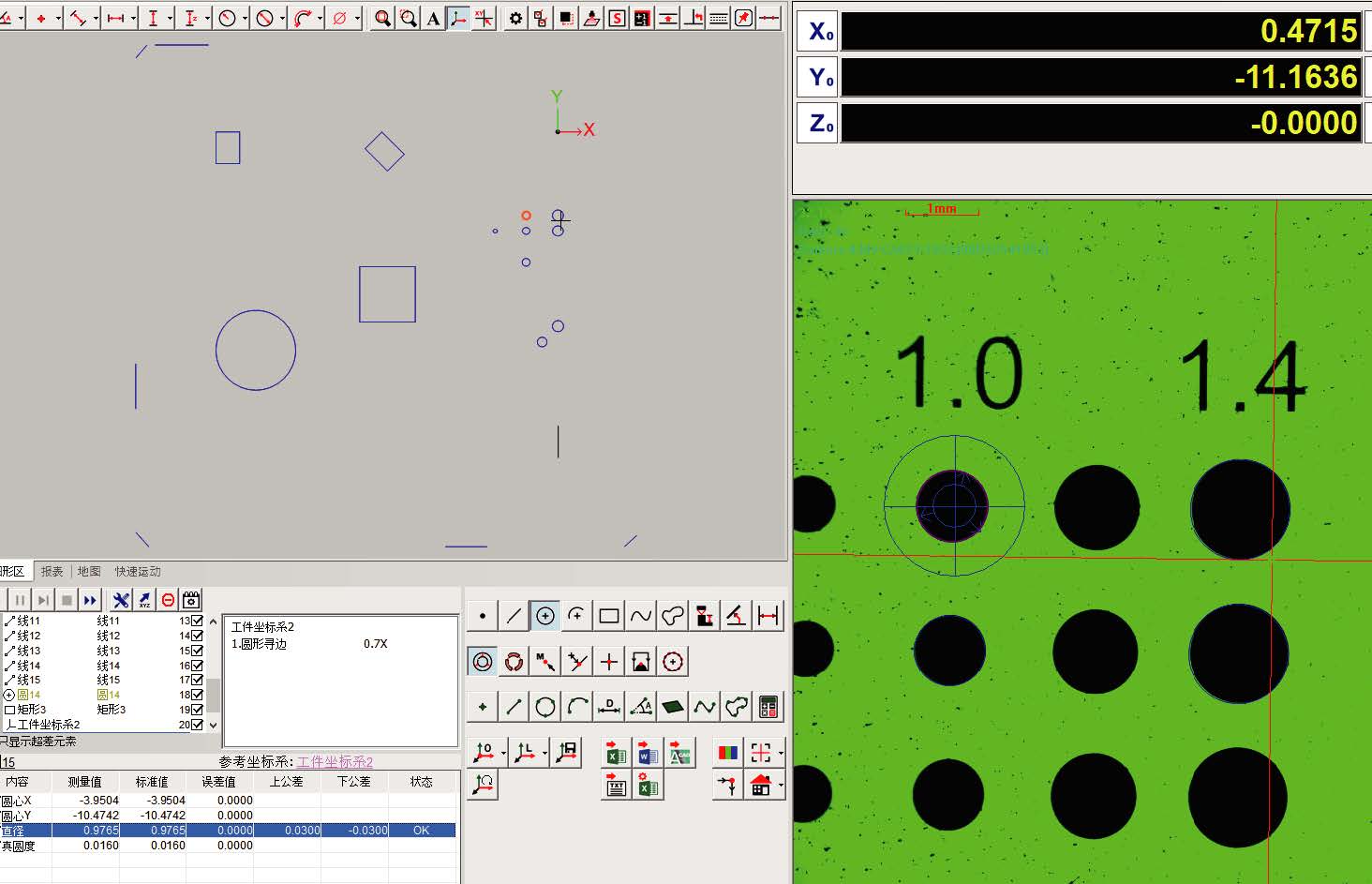

In the era of intelligence, the strength of software functions directly affects the comprehensive competitiveness of equipment. The VMC-3020P CNC vision measuring system is equipped with the self-developed Mikromea-CNC 3D software, which is powerful and easy to operate, providing users with a full-process intelligent inspection experience.

The software supports the measurement of various geometric elements, whether it is points, lines, surfaces, or complex shapes such as circles, arcs, and ellipses, and can accurately calculate the relevant parameters. At the same time, it has a free coordinate system switching function, which can quickly change the measurement reference according to different detection requirements, greatly enhancing the flexibility of measurement. The map navigation function enables users to intuitively understand the overall layout of the object being measured, accurately locate the measurement area, and avoid repeated measurements or missing key parts.

The autofocus and batch detection functions have greatly enhanced the detection efficiency. Autofocus can quickly lock onto the measurement focus, reducing manual operation time. Batch detection can simultaneously inspect multiple objects of the same specification and automatically generate inspection reports, significantly lowering labor costs. It is particularly suitable for quality spot checks and full inspections in large-scale production. Additionally, the software supports online SPC data analysis, enabling real-time statistics and analysis of inspection data, helping enterprises promptly identify potential issues in the production process and achieve early warning and continuous improvement of quality.

Widely applied, it contributes to the high-quality development of multiple industries. With all-round advantages, the VMC-3020P CNC vision measuring system has extremely wide application scenarios and has become an indispensable detection device in many industries, providing strong support for the high-quality development of various fields.

In the field of electronic manufacturing, it shoulders the responsibility of precise inspection. It can not only conduct high-precision measurements of key dimensions such as the length and width of chips and the pitch of pins, but also meticulously examine whether the circuit layout of PCB boards is regular and check for any quality issues such as short circuits or open circuits, ensuring that electronic components and PCB boards meet production standards and fortifying the defense line for the stable operation of electronic products.

In the field of mechanical processing, equipment serves as the "key defense line" for quality control. It can precisely measure the dimensional accuracy of complex components, such as the pitch of gears and the size deviation of holes, and can also monitor in real time the wear degree and edge condition of processing tools. Based on the detection results, enterprises can promptly adjust processing parameters or replace tools, effectively enhancing the precision of mechanical processing and product quality.

The entire process of mold manufacturing cannot do without the support of this equipment. From the measurement of the contour dimensions and surface roughness of the mold cavity to the detection of the fit clearance between the cavity and the core, it can provide accurate data basis, indicating the direction for mold repair and improvement, ensuring that the products formed by the mold meet the quality standards, while extending the service life of the mold and reducing production losses.

In the field of automotive manufacturing, equipment plays a crucial role in the inspection of components and appearance. Whether it is the measurement of the hole diameter of engine parts, the diameter tolerance of shaft parts, or the flatness and curvature of the car body surface, it can precisely control and ensure that the overall performance of the car is stable and the appearance quality meets industry standards.

In the field of scientific research, it provides reliable support for precise measurement. Whether it is the measurement of the microstructure dimensions of new materials or the detection of the assembly accuracy of components in experimental devices, it can provide accurate data, facilitating the smooth progress of scientific research projects and the verification of research results.

In the field of education, it has become a "practical teaching aid" for measurement and inspection-related majors. Through teaching demonstrations, it enables students to have an intuitive understanding of the working principle and operation process of the vision measuring system. At the same time, it provides equipment support for students' practical courses, helping them master high-precision measurement skills and enhance their professional qualities.

The quality inspection of products in the light industry also cannot do without it. From the wall thickness and dimensional deviation detection of plastic products to the measurement of the minute dimensional accuracy of watch parts, it ensures that light industry products meet market demands and quality standards, and avoids the impact on product competitiveness due to dimensional issues.

As an important piece of equipment in the metrology room and laboratory of the metrology verification department, it also undertakes the responsibility of standardized testing, calibrating the accuracy of small measuring tools, and verifying the dimensional consistency of mass-produced standard parts to ensure that all kinds of measuring instruments and products comply with national or industry verification standards.

The VMC-3020P CNC vision measuring system has set a benchmark in the field of metrology and inspection with its high precision, multi-functionality and high stability. It plays an irreplaceable role in ensuring production quality, improving production efficiency, promoting scientific research and innovation, and cultivating professional talents. In the future, as the precision requirements of various industries continue to increase, the VMC-3020P CNC vision measuring system will surely continue to be upgraded and optimized, contributing to the high-quality development of more fields.